CONTROL THROTTLE 2WFCE40S500L-1X/M/24A1

Manufacturer: Bosch Rexroth

Material #: R901388128

Model : 2WFCE40S500L-1X/M/24A1

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

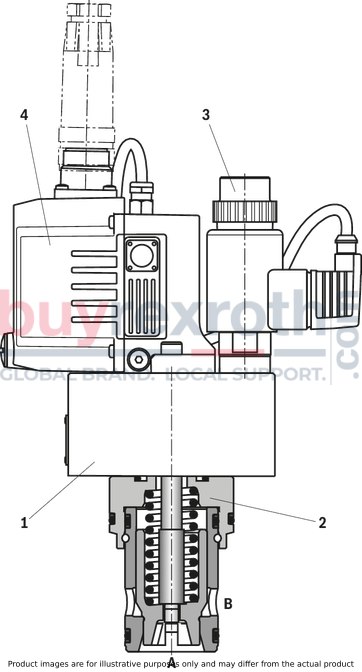

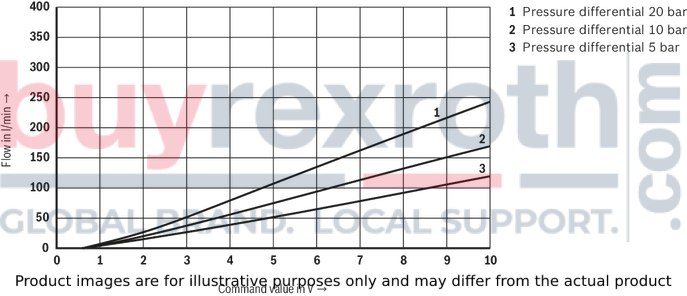

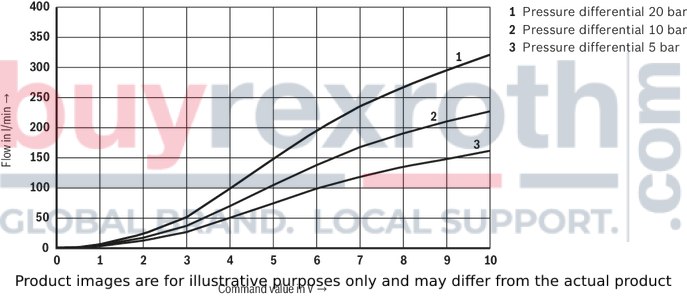

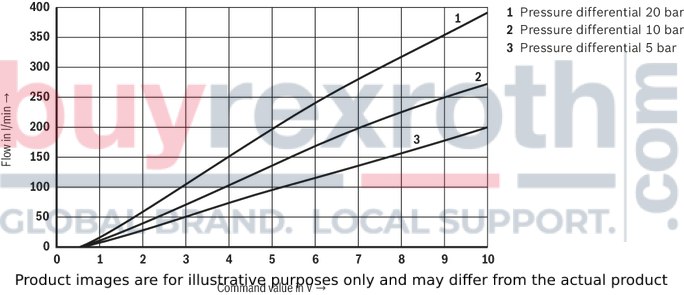

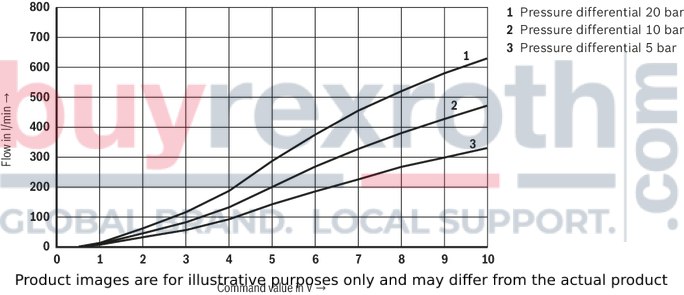

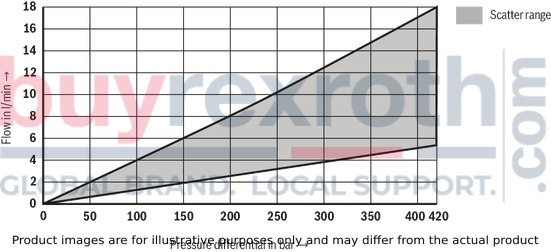

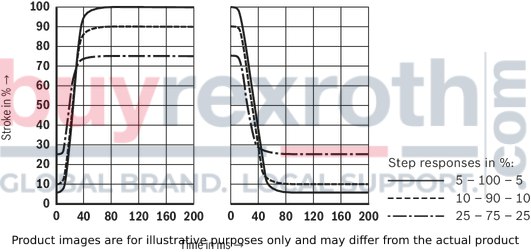

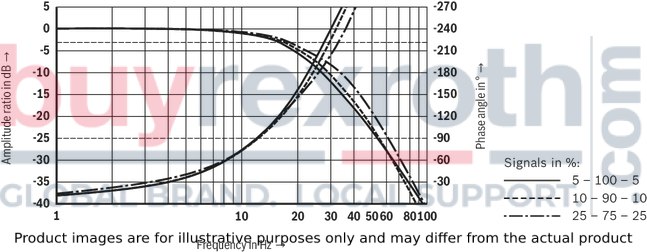

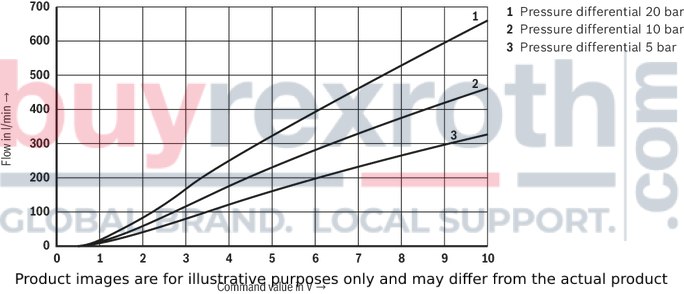

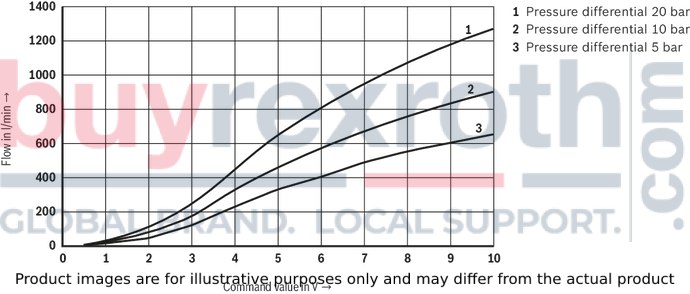

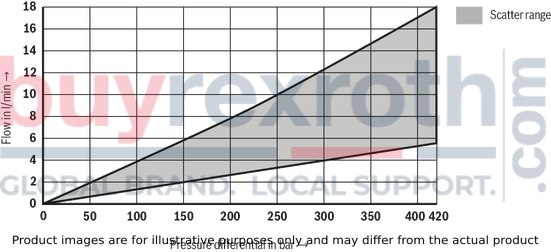

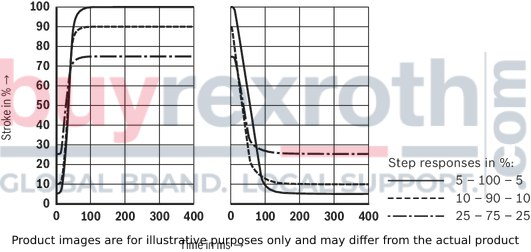

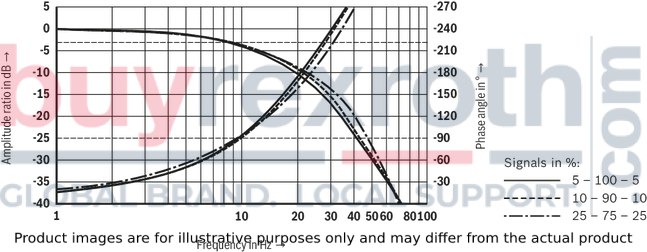

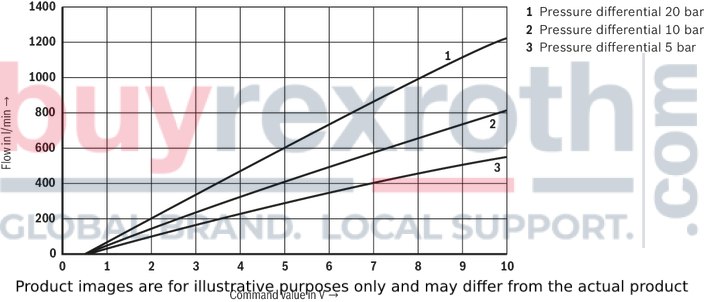

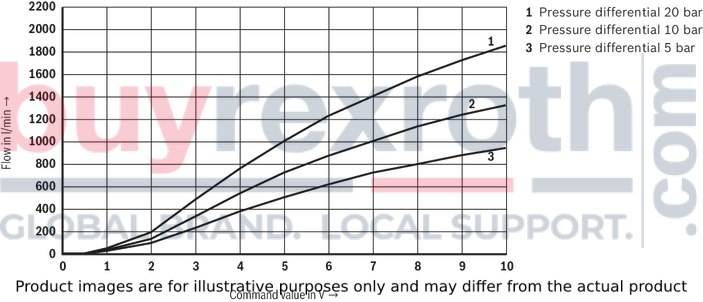

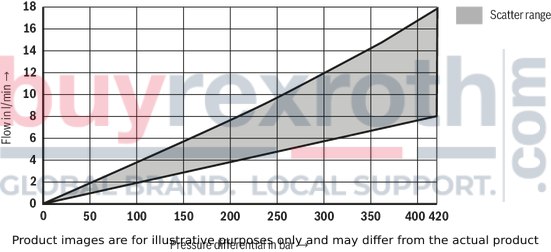

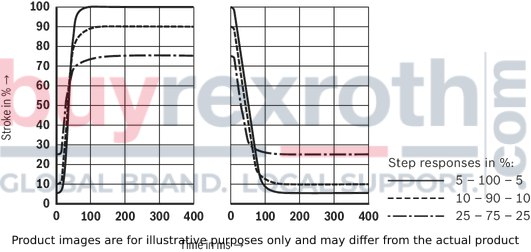

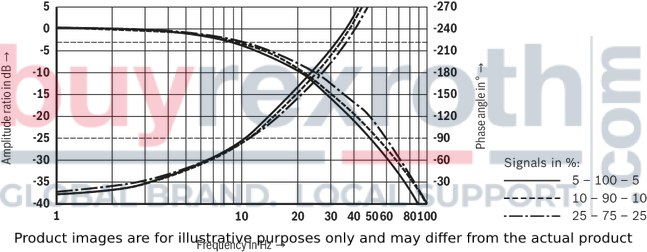

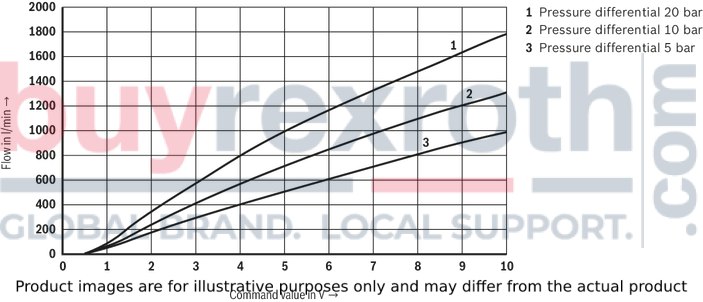

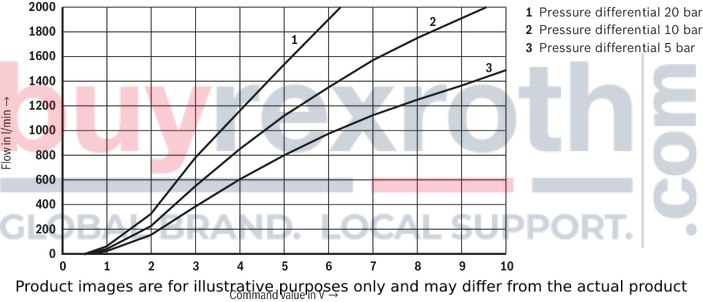

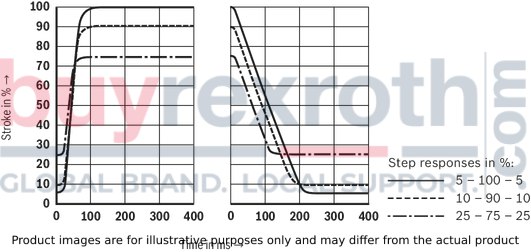

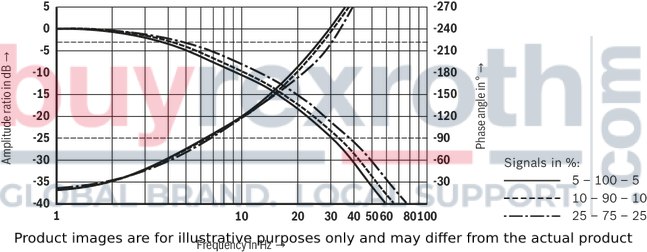

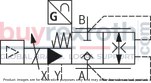

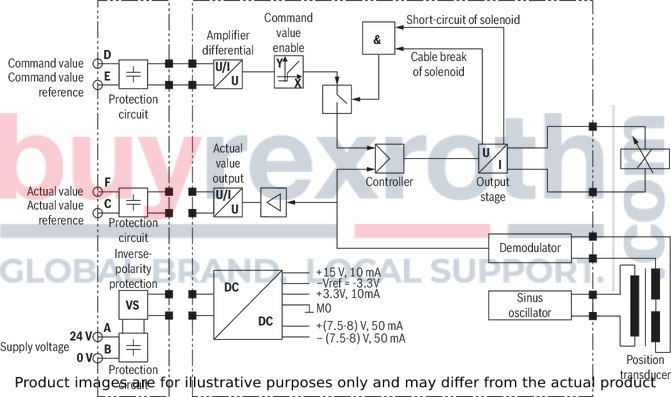

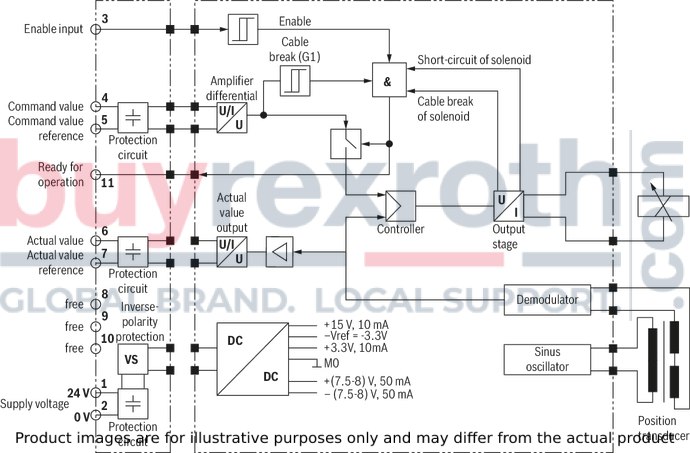

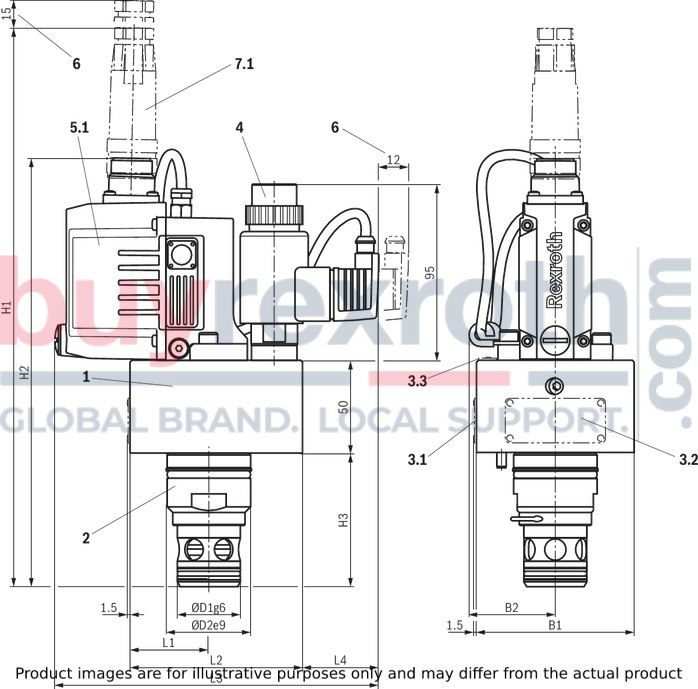

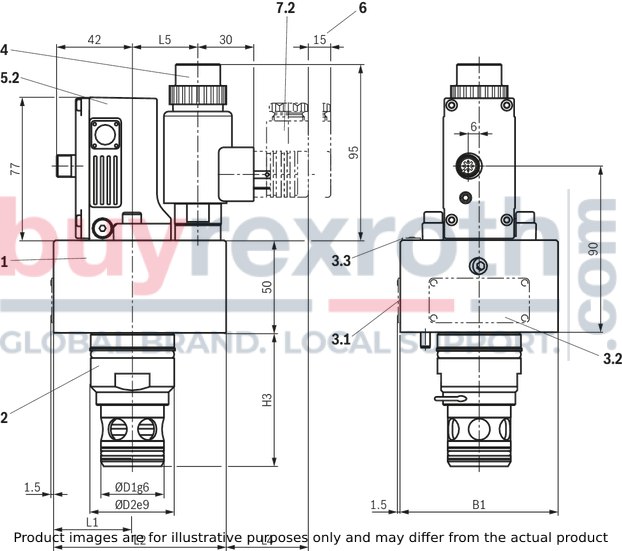

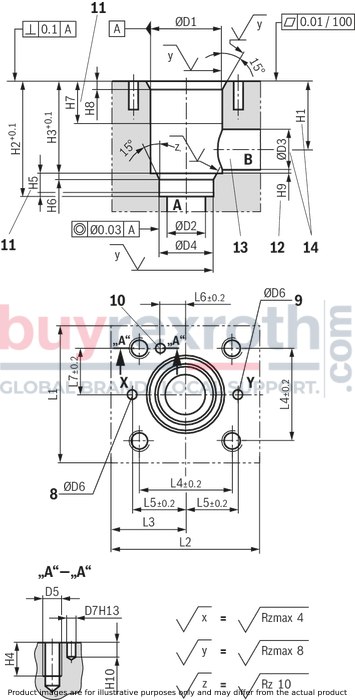

The Bosch Rexroth 2WFCE40S500L-1X/M/24A1 (R901388128) is a high-performance industrial hydraulic valve designed for reliable control of oil flow in response to command signals. It features integrated electronics, including a position transducer and an analog interface, ensuring high accuracy through internal piston position feedback. The spool valve operates with linear flow characteristics and has a spool symbol for A to B and B to A directions.

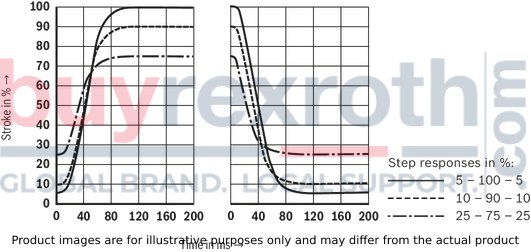

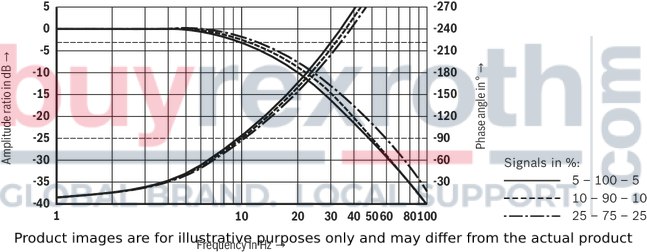

This pilot-operated proportional directional valve is comprised of a cover, main stage, pilot control valve with proportional solenoid, and the aforementioned integrated electronics or an optional external control electronics module amplifier. It reacts to control deviations by adjusting the solenoid-activated pilot control valve, thereby controlling the main stage's spool until the deviation is corrected.

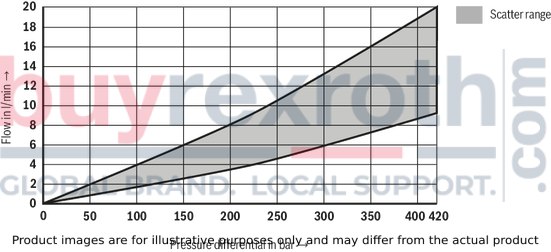

The Bosch Rexroth 2WFCE40S500L-1X/M/24A1 offers a robust design capable of withstanding pressures up to bar and features high vibration resistance according to DIN EN standards. It can operate in ambient temperatures up to °C. Its precise control is due to its high response sensitivity and minimal hysteresis.

For safety, the valve has a failsafe position that it defaults to in case of power failure or cable breakage, ensuring that flow between ports A and B is blocked securely. Additionally, it adheres to CE electromagnetic compatibility standards as per EU directives.

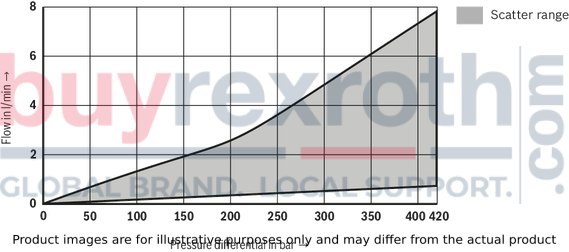

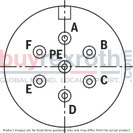

The valve's flexibility comes from its ability to be used in conjunction with a pressure compensator for pressure-compensated flow control. It has standardized installation dimensions according to ISO standards and offers various connectors/interfaces options.

With a nominal flow rate capacity, multiple switching positions, and various types of actuation including electrical with integrated electronics, this Bosch Rexroth cartridge valve represents reliability for hydraulic systems requiring precise flow management. It accommodates hydraulic fluids such as HL, HLP, HLPD, HVLP, HVLPD, HFC with NBR seals and requires a supply voltage of VDC.

$7,306.00 USD

Availability: 8 In Stock

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $7,123.35 USD | $182.65 USD |

| 25+ | $6,940.70 USD | $365.30 USD |

Qty: Delivered as early as January 22, 2026 when ordered in