***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

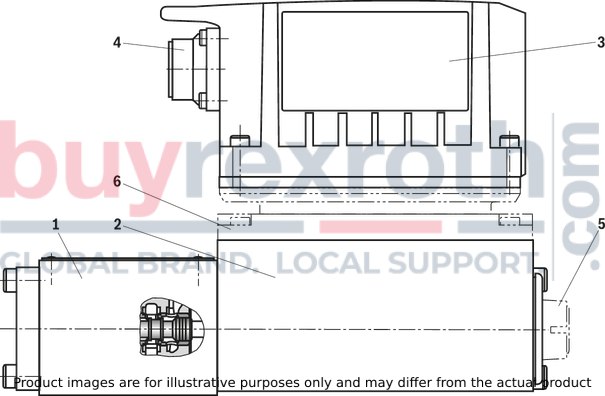

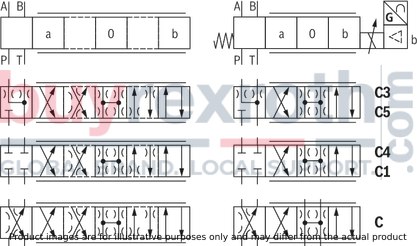

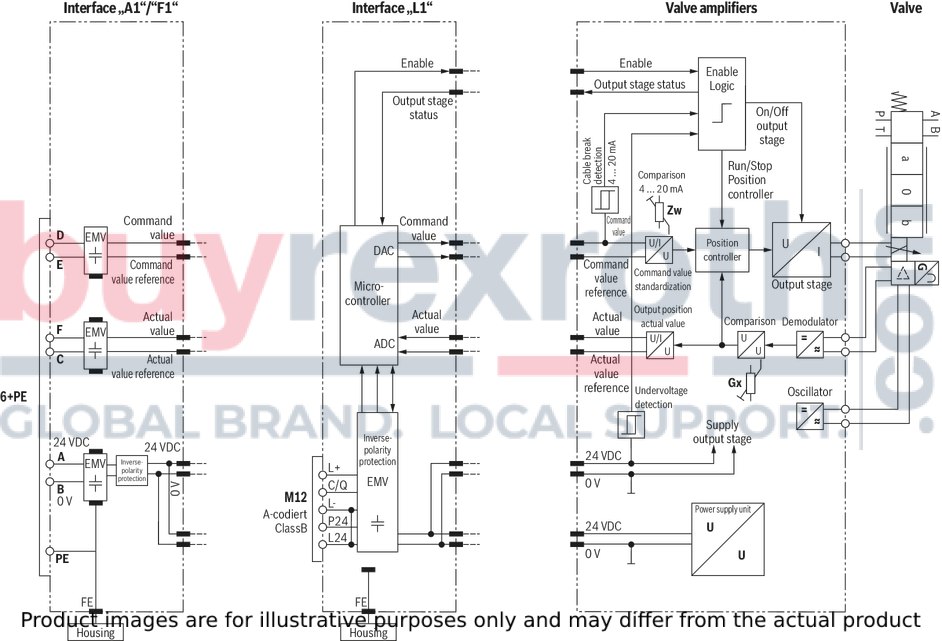

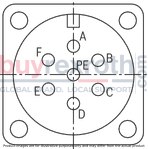

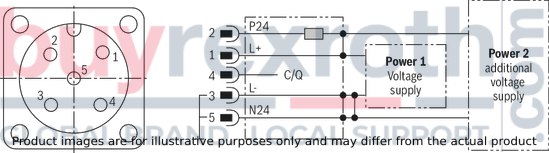

The Bosch Rexroth 4WRPEH6C3B02L-3X/M/24F1 (R901382336) is a high-response directional control valve designed for advanced hydraulic control applications. This valve is equipped with electrical position feedback and integrated onboard electronics (OBE), offering precise manipulation of fluid flow within hydraulic systems. The model features a valve housing, a control spool, and sleeve of servo quality, as well as a control solenoid with an integrated position transducer. It may also include an optional electronics protection membrane to safeguard against condensate formation in varying environmental conditions.

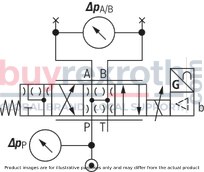

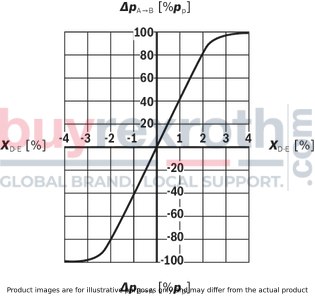

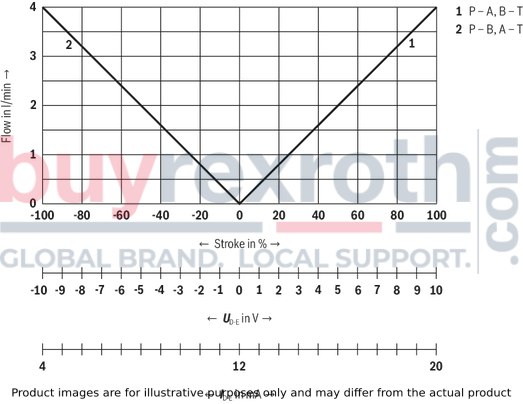

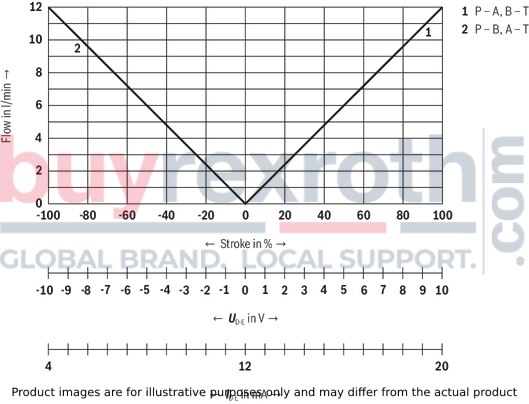

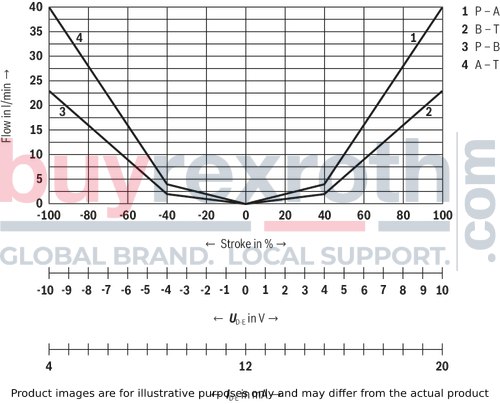

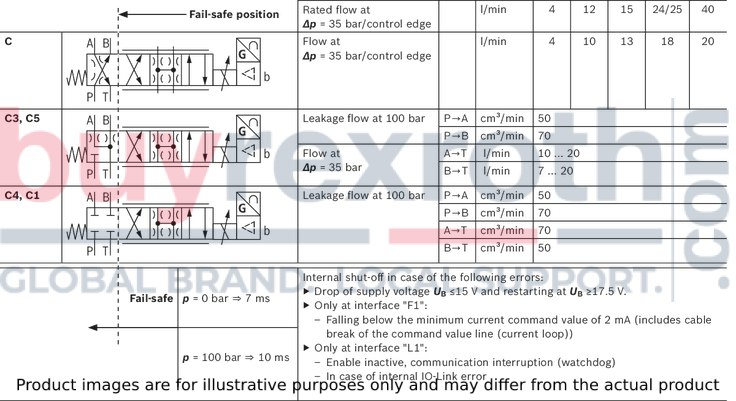

The WRPEH series valve operates by comparing the command value to the actual spool position, adjusting the control spool via the solenoid force accordingly. The OBE ensures proportional stroke control relative to the input command value, maintaining high precision in operation. In the event of power loss or certain faults such as supply voltage drops or communication errors, the valve defaults to a failsafe position due to spring tension release, ensuring system safety.

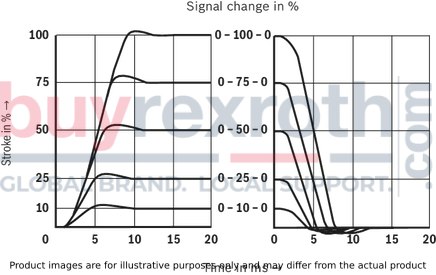

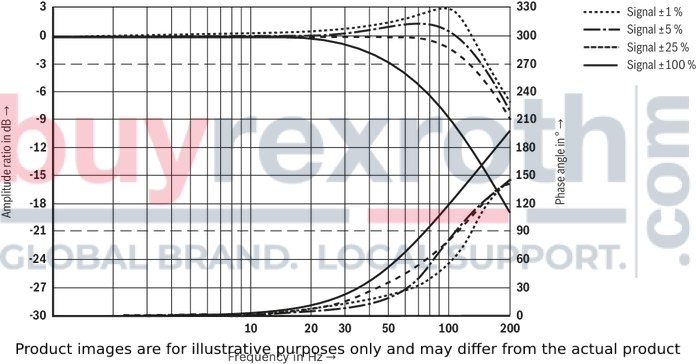

Additionally, this model can be optionally fitted with a damping plate that serves to reduce acceleration amplitudes affecting onboard electronics at frequencies above 20 Hz. However, it is not recommended for low-frequency applications under 20 Hz.

This Bosch Rexroth valve is recognized for its reliable performance and robust design. It does not require pilot oil, making it energy-efficient. Its high-quality construction ensures long-lasting durability and responsiveness suitable for positioning, velocity, and pressure control tasks within hydraulic circuits.

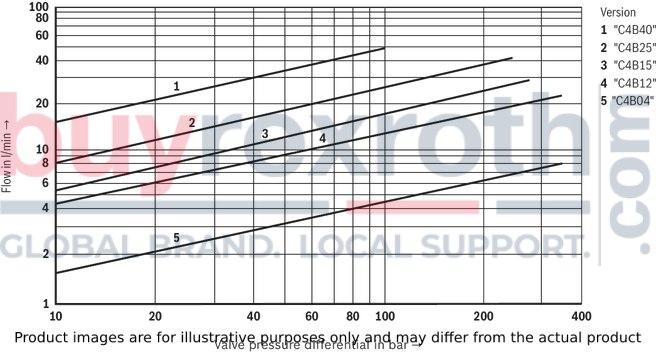

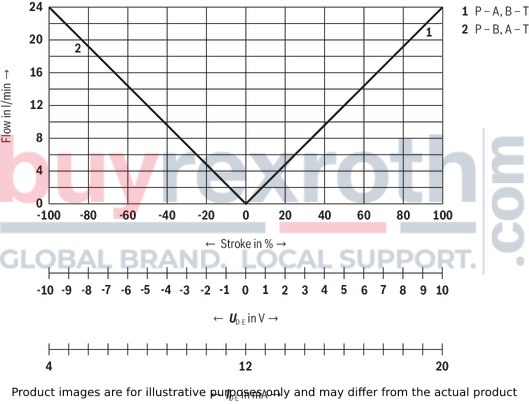

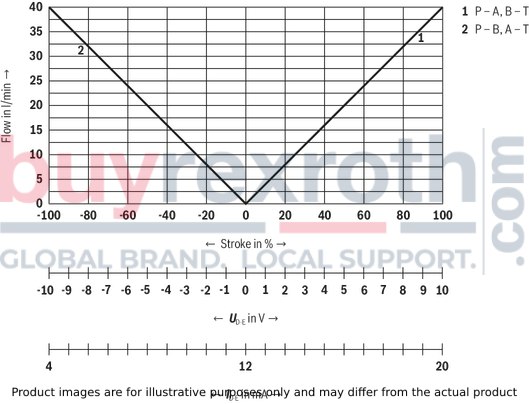

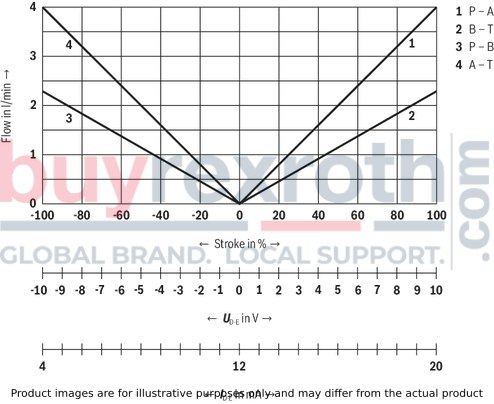

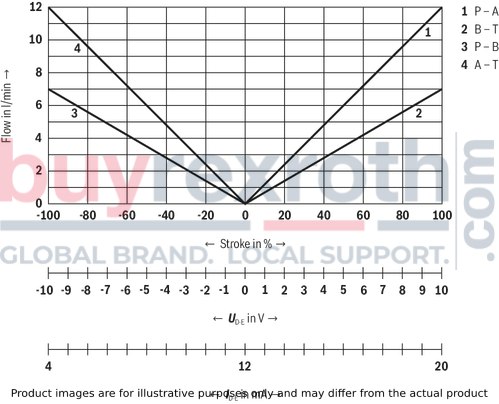

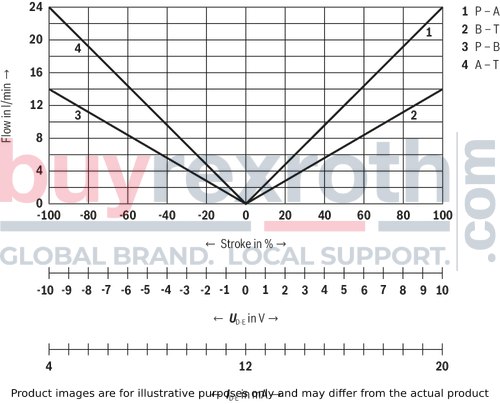

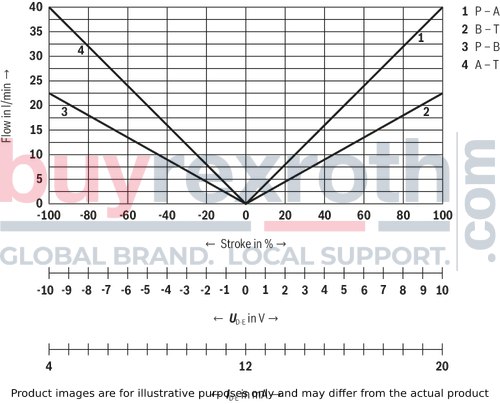

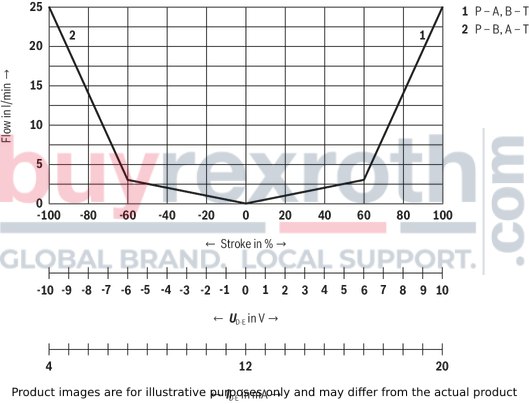

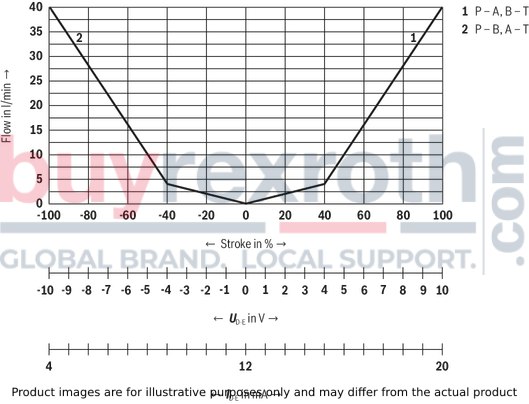

The unit's size and component series allow it to handle maximum operating pressures up to a specified bar level while facilitating a nominal flow rate measured in liters per minute (l/min). The optional IOLink interface enhances connectivity options for modern industrial applications requiring precise electronic communication for effective hydraulic system management.

$6,614.00 USD

More are expected on August 26, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $6,448.65 USD | $165.35 USD |

| 25+ | $6,283.30 USD | $330.70 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 26, 2026 when ordered in