Commissioning, maintenance and operating instructions

General Information

Observe the documentation for the machinery. Also observe the documentation pertaining to the other components, assemblies and partly completed machinery, which form part of the complete machinery. Observe the generally applicable, legal or otherwise binding European and national regulations as well as the relevant legislation for your country pertaining to the prevention of accidents and protection of the environment. Operating instructions according to data sheet of the accumulator Depending on the country of installation, national pressure vessel regulations need to be complied with. In the standard, the country acceptance is effected according to BA, CE as well as for China and Russia Other acceptances on request. Please indicate the country of installation in the order. Keep all documents included in the delivery in a safe place; they will be required by the expert in recurring tests. The machine end-user will have sole responsibility for complying with existing provisions. The accumulator stations in this edition are assemblies in the sense of directive 2014/68/EU, article 2, section 6 (Pressure Equipment Directive).However, they are not intended for exclusive commissioning. They are installed as a component of a larger assembly or system. The accumulator stations described here contain the entire equipment which is required for safety reasons according to DIN EN ISO 4413. The accumulator stations must not be modified; otherwise, the operating license according to directive 2014/68/EU will be lost and the dealer and/or manufacturer warranty will be forfeited. The accumulator stations may only be operated within the admissible limit values. Repairs may only be carried out by the manufacturer or their authorized dealers and agencies. Repairs performed by third parties invalidate the approval and release the manufacturer from all claims resulting from an unauthorized intervention. Assembly and maintenance must be implemented by authorized, instructed persons only.

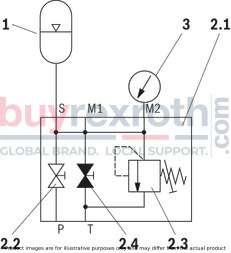

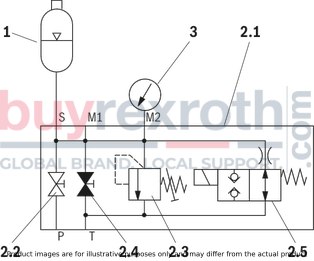

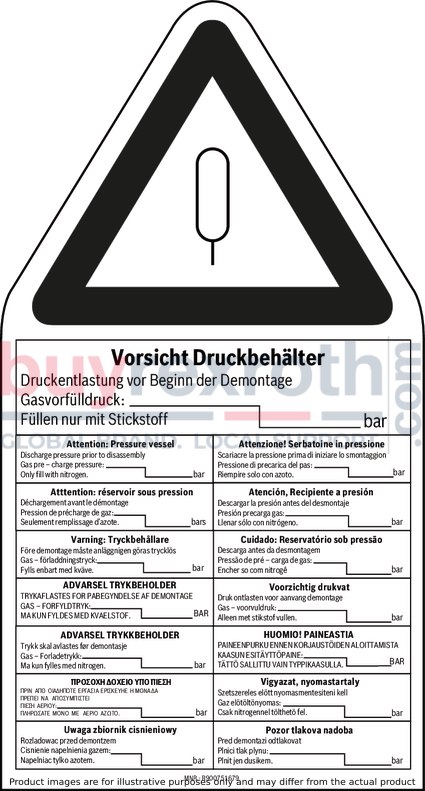

The accumulator stations are provided with signs:1. Name plate specifying the pressure rating, identifies the device2. Functional sign, identifies the components and elementary lever positions3. Warning sign, has to be clearly visible and attached at the device or next to it.Usually, the warning sign is in the languages according to the country acceptance. Other languages on request.

For hydraulic systems with one or several hydraulic accumulators whose warning signs are not visible after installation into the machine, an additional warning sign has to be attached visibly to the system, stating:

"CAUTION - system contains hydraulic accumulators."

The circuit diagram has to contain the same notice. With mounting "B" and "K", the warning signs and functional signs are supplied loosely and must be attached to or close to the accumulator station in a clearly visible position. The attachment of the signs must already be considered in the design.

1: Name plate

|

3: Warning sign

|

2: Functional sign

|

Commissioning - Operating instructions according to data sheet of the accumulator!

DANGER

Do not charge hydraulic accumulators with oxygen or air. Explosion hazard!

Prior to the initial commissioning, the hydraulic accumulator must be filled with nitrogen of class 4.0, pure (N2 content 99.99 vol. %).The preset gas pressure necessary for the operation is indicated in the circuit diagrams and operating instructions. Only use suitable filling and testing devices for filling.We recommend using the charging and test devices by Bosch Rexroth according to data sheet 50150.

WARNING

Risk of injury caused by improper assembly. Hydraulic accumulators are energy stores. They may supply the energy for uncontrolled movements to actuators. Before beginning any repairs, the system must be depressurized on the oil and gas side and protected against unauthorized re-start. Do not carry out welding and soldering works or any mechanical processing at the accumulator tank!Any kind of work at the product invalidates the declaration of conformity and the operating license!– Explosion hazard due to welding and soldering works!– Danger of bursting during and after mechanical processing. A warning sign is enclosed to the accumulator station. It is to be attached to or close to the accumulator station in a clearly visible position.

Maintenance

ATTENTION

In case of damage at the accumulator bladder or diaphragm, the accumulator will lose its function immediately. Loss of the initial gas tension will lead to damage at the accumulator bladder or the accumulator diaphragm if operation of the system is continued nevertheless. Check the initial gas tension in regular intervals.

Legal provisions

Hydraulic accumulators are pressure vessels and subject to the application national provisions and/or regulations valid at the place of installation. In Germany, the Ordinance on Industrial Safety and Health (BetrSichV) applies. As a standard, country acceptances are effected according to BA, CE as well as for China and Russia. Other acceptances on request. Special regulations are to be observed in shipbuilding, aircraft construction, mining, etc. Design, production and testing are effected according to the data sheets according to AD 2000. Installation, equipment and operation are controlled by the "Technical rules Pressure vessels" (TRB).

Note pursuant to the EC Machinery Directive 2006/42/EC, according to annex II part 1, section A, manufacturer's declaration:

The assemblies were manufactured in accordance with the harmonized standards DIN EN ISO 4413, DIN EN ISO 12100, EN 983 and EN 60204-1. Commissioning is prohibited until it was confirmed that the machine into which the assemblies are to be integrated complies with the regulations laid down in the EC Directives.