FLOAT SWITCH ABZMS-41-1X/0500/M2/AC-K14

Manufacturer: Bosch Rexroth

Material #: R901269276

Model : ABZMS-41-2X/0500/M2/AC-K14

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth ABZMS-41-1X/0500/M2/AC-K14 (R901269276) is a sophisticated float switch designed for precise fluid level control in hydraulic power unit tanks. This device features two switching contacts that can be set to specific switching points, allowing for accurate monitoring and maintenance of fluid levels. With a maximum pressure capacity and an electrical connector pole PE conforming to DIN EN standards, it ensures reliable operation under various conditions.

The float switch is capable of handling a variety of hydraulic fluids, including HLP, HFAE, HFC, HFDR, HFDU, HETG, HEES, and HEPG. It comes with surge protection for added durability and conforms to CE standards for electromagnetic compatibility within the EU. The unit has a length specification and includes a display that provides visual feedback on the system's status.

Supply voltage requirements range from VDC to VAC, making it versatile for different power setups. The device has an output signal consisting of two switching outputs, ensuring effective communication with other system components. The float switch weighs in at . kg and is part of Productgroup ID.

In terms of functionality, the ABZMS-41-1X/0500/M2/AC-K14 offers adjustable reed contacts within its sliding tubes that are activated by permanent magnets in the float as fluid levels change. Users can adjust the switching points and easily convert contact types by rotating them 180 degrees. Additionally, it features a resistance measuring chain for continuous level recording and temperature monitoring capabilities with bimetal temperature contacts or PT sensors.

For more advanced needs, this model includes a microprocessor-controlled display and control unit that allows for easy parameter setting and monitoring through an intuitive menu navigation system. It provides up to four freely adjustable PNP switching outputs or alternatively two programmable PNP outputs along with an analog output for continuous measurement.

Overall, this Bosch Rexroth float switch is designed to offer high precision in fluid level management with extensive configuration options to meet diverse application requirements.

$367.00 USD

Availability: 2 In Stock

Qty: Delivered as early as January 26, 2026 when ordered in

Qty: Delivered as early as July 13, 2026 when ordered in

Float switch

Unpacked Weight: 1.53 kg

Float switches are switching devices operated by a float moved by fluid. These are used to control fluid levels in power unit tanks.

Three series are available:

Float switches typeABZMS…M with a maximum of four adjustable switching contacts normally closed contact/ normally open contact or a maximum of three switching contacts and optionally fixedly set temperature contact as normally closed contact for 60 °C, 70 °C or 80 °C Float switches type ABZMS…RTA with resistance measuring chain (level) and resistance thermometer (temperature) with analog output from 4 to 20 mA. Float switches type ABZMS…D with resistance measuring chain and resistance thermometer as with type ABZMS...RTA and additional display and control unit for level and temperature setting.Level function

Level contacts:

The sliding tubes contain the adjustable reed contacts (normally closed contact and normally open contact) that are switched by the permanent magnets installed in the float.

If with decreasing oil level, the float reaches the switching points, the contacts are magnetically operated. The spool positions of the contacts are maintained until the float passes the switching points once again due to the increasing oil level.

The switching points can be adjusted in the device.

Rotating the contacts by 180° changes the switching function; the normally closed contact type becomes a normally open contact or vice versa.

Resistance measuring chain:

The sliding tube contains the resistance measuring chain (contact distance 5 mm / resolution) for the continuous recording of the filling level height. If the individual reed contact is switched (closed) by the permanent magnet located in the float, a resistance will in each case be activated.

The added resistance value is converted by a transformer into 4 … 20 mA.

Temperature function

Temperature contact:

At the lowest point within the sliding tube, the bi-metal temperature contacts are attached to the circuit board and secured by means of a shrinkable tubing (the same procedure is used with the versions with PT 100 temperature sensor and resistance thermometer with analog output 4 … 20 mA). If the desired temperature switching point is reached, the bi-metal contact is opened or closed.

Temperature sensor PT100:

The PT100 consists of a temperature sensor guaranteeing continuous temperature recording. In this connection, the max. cable length of [si]6 m[/si][mp]236 in[/imp] is to be observed.

Resistance thermometer with measuring transducer, output 4 … 20 mA:

The PT100 resistance thermometer with measuring transducer is also attached to the circuit board in the sliding tube. The temperature-dependent signal is converted into a linear current change from 4 … 20 mA.

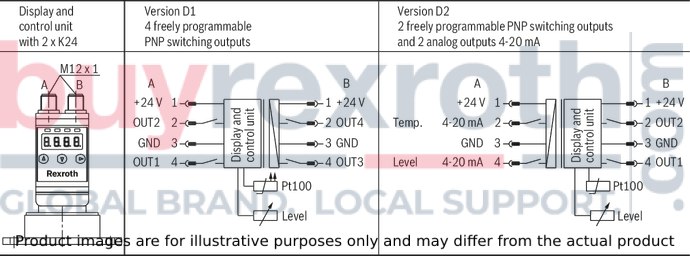

Display and control unit function (version D)

The micro-processor controlled display and control unit processes the analog input signals for the analysis of the level and temperature control. Level and temperature can be set at the control unit in an easy menu navigation by means of pushbuttons and the settings can be read off at the LED display.

The display and control unit has a four-digit, red seven-segment LED display and 3 pushbuttons for the operation as well as up to 4 LEDs integrated in the front plate for the display of alarm conditions.

Apart from that, the device has four freely adjustable PNP switching outputs plus the adjustable switch-back points (version D1) and alternatively (version D2) two freely programmable PNP switching outputs and 2 x 4 … 20 mA output for the continuous measurement of oil level and temperature. The switching conditions are shown in the display.

The output 4 … 20 mA can optionally be set to 0 … 10 V, 2 … 10 V or 0 … 5 V.

Depending on the setting, the display shows the measured temperature or filling level value in the desired unit (°C, °F, L, cm, %, inch or mm). By default, the temperature display is set to °C.

During the setting and/or programming of the corresponding process parameters, the parameter values and/or the related menu items are shown in the display.

In case of energy supply failure, all input values will be stored, the max/min values can be called from a permanent memory, if necessary.

Parameterization

The menu navigation is based on the VDMA standard sheet for fluid sensors 24574-1.

The operating menu is designed hierarchically as tree structure.

That means that frequently used functions and adjustment points are quickly accessible and rarely used menu items can be found in a submenu.

Using the ▲ and ▼ keys, the corresponding parameters are set and/or the next menu item is displayed.

Using the ► key, the selected menu item is selected and/or the set parameter is accepted and stored.

The parameter may be a numerical value and a selection of functions (e.g. NO [output as normally open contact], NC [output as normally closed contact] or i1 [analog output 4 … 20 mA]).

After confirmation of a parameter or function selection by means of the ► key, the display will switch back to the current menu item. Then, you can use ▲ and ▼ to display the next menu item and ► to select it.

| Surge protection |

| Float switches are switching devices operated by a float moved by fluid. |

| Two switching contacts |

| Switching points: 280 mm /160 mm |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Max. pressure | 1 |

| Output signal | 2 switching outputs |

| Supply voltage | 10...230 V AC/DC |

| Electrical connector | Connector 4-pole (3 + PE) |

| Display | yes |

| Electrical connection description | Connector 4-pole (3 + PE) according to EN 175301-803 |

| Conformity description | CE – electromagnetic compatibility 2014/30/EU |

| Conformity | CE |

| Hydraulic fluid | HLP,HFA-E,HFC,HFDR,HFDU,HETG,HEES,HEPG |

| Productgroup ID | 9,10,11,12,13,14 |

| Length | 500 |

| Weight | 1.53 |

Ordering code

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

||||||

|

ABZM |

S |

‒ |

41 |

‒ |

1X |

/ |

/ |

/ |

‒ |

|

Power unit accessories |

||

|

01 |

Measuring devices |

ABZM |

|

02 |

Float switches |

S |

|

03 |

Version |

41 |

|

04 |

Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) |

1X |

|

Ordering length in mm |

||

|

05 |

L = 370 mm |

0370 |

|

L = 500 mm |

0500 |

|

|

L = 800 mm |

0800 |

|

|

L = 1000 mm |

1000 |

|

|

L = 1200 mm |

1200 |

|

|

Level and temperature measurement 1) |

||

|

06 |

Number of level contacts normally closed contact/normally open contact 2) |

|

|

1 x |

M1 |

|

|

2 x |

M2 |

|

|

3 x |

M3 |

|

|

4 x |

M4 |

|

|

Number of level contacts normally closed contact/normally open contact and temperature contact 70 °C normally closed contact 3) |

||

|

1 x |

M1-T70F |

|

|

2 x |

M2-T70F |

|

|

3 x |

M3-T70F |

|

|

Number of level contacts normally closed contact/normally open contact and temperature sensor PT100, output resistance signal Ω |

||

|

1 x |

M1-TS |

|

|

2 x |

M2-TS |

|

|

3 x |

M3-TS |

|

|

Number of level contacts normally closed contact/normally open contact and resistance thermometer, output 4 … 20 mA |

||

|

1 x |

M1-TA |

|

|

2 x |

M2-TA |

|

|

3 x |

M3-TA |

|

|

06 |

Resistance measuring chain (level) and resistance thermometer analog output 4 … 20 mA |

RTA |

|

Display and control unit with resistance measuring chain and resistance thermometer with four programmable PNP switching outputs |

D1 |

|

|

Display and control unit with resistance measuring chain and resistance thermometer with two programmable PNP switching outputs and two analog outputs 4 … 20 mA |

D2 |

|

|

Voltage |

||

|

07 |

VDC 10 … 36 |

DC |

|

VAC 10 … 230 |

AC |

|

|

Without temperature contact |

no code |

|

|

Electrical connection 4) |

||

|

08 |

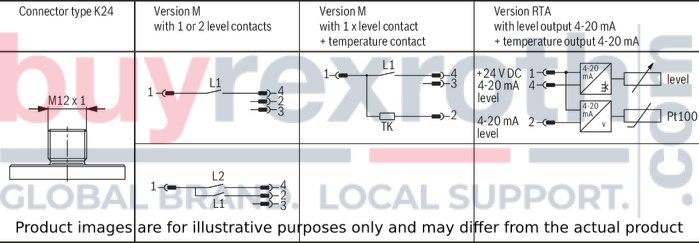

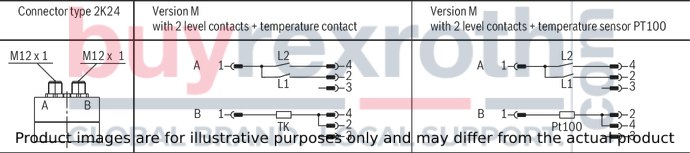

Connector, 4-pole M12 x 1 (standard) |

K24 |

|

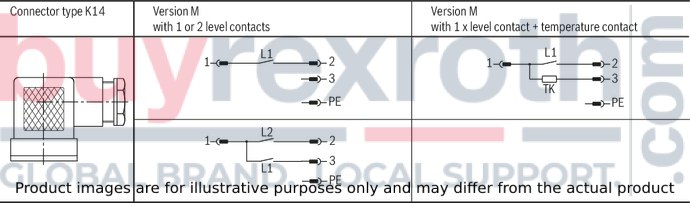

Connector 4-pole (3 + PE) DIN EN 175301-803 |

K14 |

|

|

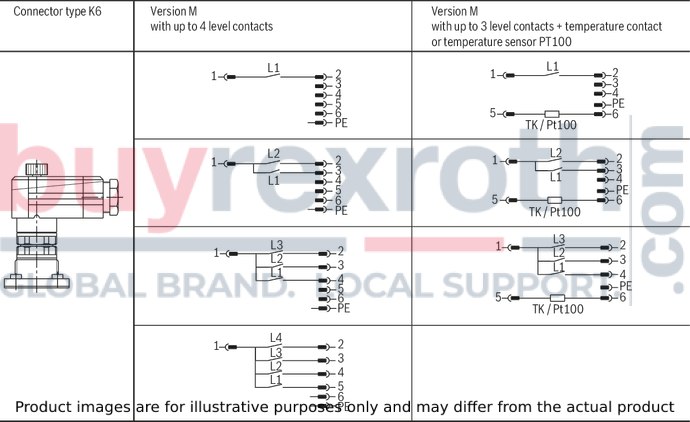

Connector 7-pole (6 + PE) DIN EN 175201-804 |

K6 |

|

| 1) | Combination possibilities function / electrical connection |

| 2) | Pinout, see “Electrical connection” |

| 3) |

Option: Temperature contact 60 °C = T60F Temperature contact 80 °C = T80F |

| 4) | Mating connectors, separate order (see R.08006) |

| Order example: | |

| Float switch with flange connection, ordering length 370 mm, two pre-set level contacts and temperature contact, normally closed contact at 70 °C, connector K24: | |

| ABZMS-S-41-1X/0370/M2-T70/DC-K24 |

|

Function |

Voltage |

|||||

|

VDC 10-36 |

VAC 10-230 |

|||||

|

K24 |

2K24 |

K14 |

K6 |

K14 |

K6 |

|

|

M1 |

X |

‒ |

X |

X |

X |

X |

|

M2 |

X |

‒ |

X |

X |

X |

X |

|

M3 |

‒ |

‒ |

‒ |

X |

‒ |

‒ |

|

M4 |

‒ |

‒ |

‒ |

X |

‒ |

‒ |

|

M1-T70F |

‒ |

X |

X |

X |

X |

X |

|

M2-T70F |

‒ |

X |

‒ |

X |

‒ |

X |

|

M3-T70F |

‒ |

‒ |

‒ |

X |

‒ |

‒ |

|

M1-TS |

‒ |

X |

‒ |

X |

‒ |

‒ |

|

M2-TS |

‒ |

X |

‒ |

X |

‒ |

‒ |

|

M3-TS |

‒ |

‒ |

‒ |

X |

‒ |

‒ |

|

M1-TA |

‒ |

X |

‒ |

X |

‒ |

‒ |

|

M2-TA |

‒ |

X |

‒ |

X |

‒ |

‒ |

|

M3-TA |

‒ |

‒ |

‒ |

X |

‒ |

‒ |

|

RTA |

X |

‒ |

‒ |

‒ |

‒ |

‒ |

|

D1 |

‒ |

X |

‒ |

‒ |

‒ |

‒ |

|

D2 |

‒ |

X |

‒ |

‒ |

‒ |

‒ |

Resistance

|

Hydraulic fluids |

||||

|

Mineral oils |

Mineral oil |

HLP |

according to DIN 51524 |

Resistant |

|

Flame-resistant hydraulic fluids |

Emulsions |

HFA-E |

according to DIN 24320 |

|

|

Water solutions |

HFC |

according to VDMA 24317 |

||

|

Phosphoric acid esters |

HFD-R |

|||

|

Organic esters |

HFD-U |

|||

|

Fast bio-degradable hydraulic fluids |

Triglycerides (rape seed oil) |

HETG |

according to VDMA 24568 |

|

|

Synthetic esters |

HEES |

|||

|

Polyglycols |

HEPG |

|||

electrical

|

Plug-in connection |

4-pole M12 x 1 (material: metal) (K24) 4-pole (3 + PE) DIN EN 175301-803 (K14) 7-pole (6 + PE) DIN EN 175201-804 (K6) |

Reed contacts of the float switches

with connection K24, K14, K6/DC

|

Switching voltage range |

V DC |

10 … 36 |

|

Maximum switching current |

A |

0.5 |

|

Maximal contact load |

VA |

10 |

Temperature contacts of the float switches

with connection K24, K14, K6/DC

|

Switching voltage range |

V DC |

10 … 50 |

|

Maximum switching current |

A |

0.5 |

|

Maximal contact load |

VA |

10 |

|

Maximum switching cycles |

100000 | |

|

Response tolerance |

K |

± 3 |

|

Hysteresis |

K |

≤10 |

|

Maximum temperature change velocity |

K/min |

1 |

Reed contacts of the float switches

with connection K14 according to DIN EN 175301-803 / K6 according to DIN EN 175201-804/AC

|

Switching voltage range |

V AC/DC |

10 … 230 |

|

Maximum switching current |

A |

0.5 |

|

Maximal contact load |

VA |

10 |

Temperature contacts of the float switches

with connection K14 according to DIN EN 175301-803 / K6 according to DIN EN 175201-804/AC

|

Switching voltage range |

V AC/DC |

10 … 230 |

|

Maximum switching current |

A |

2.5 |

|

Maximal contact load |

VA |

100 |

|

Maximum switching cycles |

100000 | |

|

Response tolerance |

K |

± 3 |

|

Hysteresis |

K |

≤10 |

|

Maximum temperature change velocity |

K/min |

1 |

Temperature sensor Pt100

|

Sensor element |

Pt100 class B DIN EN 60751 | |

|

Temperature measuring range |

°C |

0 … 100 |

|

Accuracy |

K |

± 0.8 |

Resistance measuring chain and resistance thermometer

with connection K24 for mating connector M12 x 1; 4-pole

|

Outlet 1) |

mA |

4 … 20 |

|

Resolution resistance measuring chain |

mm |

5 |

|

Maximum load resistance |

(U ‒ 9 V) / (0.02 A) | |

|

Temperature measuring range |

°C |

0 … 100 |

| 1) | Alternatively 0 … 20, 2 … 10 or 0 … 5 V adjustable |

Display and control unit

|

Power supply |

V DC |

10 … 32 | |

|

Display range |

°C |

-20 … +120 | |

|

Alarm adjustment range |

Temperature |

°C |

0 … 100 |

|

Level |

% |

0 … 100 | |

|

l |

0 … 999 | ||

|

Switching points |

4 programmable switching outputs (2 level + 2 temperature) | ||

|

Housing design |

PA, IP65 (antistatisch) | ||

|

Current consumption upon switch-on |

more than 100 ms |

mA |

≈ 100 |

|

Current consumption during operation |

with UB 24 V |

mA |

≈50 |

|

Switching output |

|

PNP | |

|

Maximum switching power |

A |

0.5 | |

|

Operation |

3 keys | ||

For applications outside these parameters, please consult us!

With two switching contacts

With two switching contacts and one temperature contact

With resistance measuring chain/resistance thermometer

With display and control unit, resistance measuring chain/resistance thermometer

Connection versions and pin assignment

By default, the switching point L1 is set as normally closed contact and switching points L2 to L4 as normally open contact. The switching points can be adjusted in the device.

Rotating the contacts by 180° changes the switching function; the normally closed contact type becomes a normally open contact or vice versa.

Pre-set switching points Type M

|

Float switch Ordering length "L" |

Number of switching points |

||||

|

Switching points pre-set |

|||||

|

|

1 |

2 |

3 |

4 |

|

|

mm |

mm |

mm |

mm |

mm |

|

| 370 | L1 | 220 | 220 | 220 | 280 |

| L2 | - | 140 | 140 | 220 | |

| L3 | - | - | 60 | 140 | |

| L4 | - | - | - | 60 | |

| 500 | L1 | 280 | 280 | 280 | 340 |

| L2 | - | 160 | 160 | 280 | |

| L3 | - | - | 60 | 160 | |

| L4 | - | - | - | 60 | |

| 800 | L1 | 600 | 600 | 600 | 700 |

| L2 | - | 400 | 400 | 600 | |

| L3 | - | - | 200 | 400 | |

| L4 | - | - | - | 200 | |

| 1000 | L1 | 700 | 700 | 700 | 800 |

| L2 | - | 500 | 500 | 700 | |

| L3 | - | - | 200 | 500 | |

| L4 | - | - | - | 200 | |

| 1200 | L1 | 800 | 800 | 800 | 1000 |

| L2 | - | 600 | 600 | 800 | |

| L3 | - | - | 300 | 600 | |

| L4 | - | - | - | 300 | |

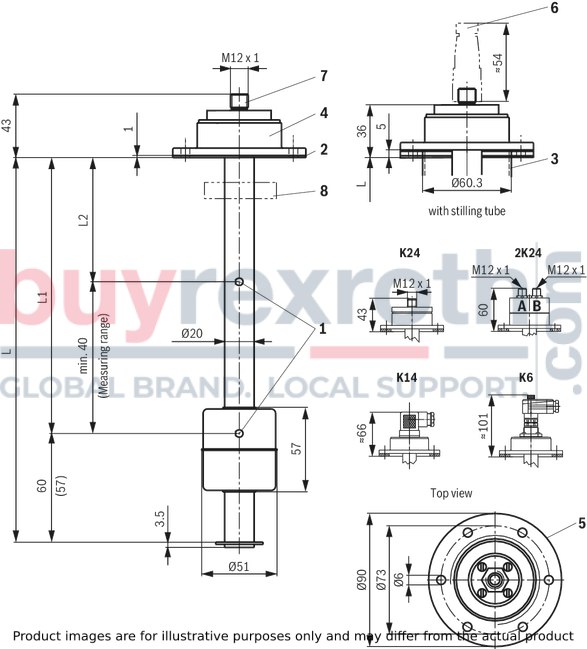

Dimensions:

Float switch with level and temperature contacts (version M - T..F)Float switch with resistance measuring chain and resistance thermometer (version RTA)Dimensions in mm

|

1 |

Switching points |

|

2 |

Flat seal |

|

3 |

Stilling tube from L = 500 mm |

|

4 |

Name plate |

|

5 |

Installation opening of the tank |

|

6 |

Mating connector for plug-in connections K24 (M12 x 1), see table "Mating connector" |

|

7 |

Connector K24; 4-pole M12 x 1 |

|

8 |

Stroke limitation ring set to 20 mA (Type RTA) |

|

Version M: L1 = min. 70 mm |

|

|

Version RTA: L1 = L ‒ min. 57 mm |

|

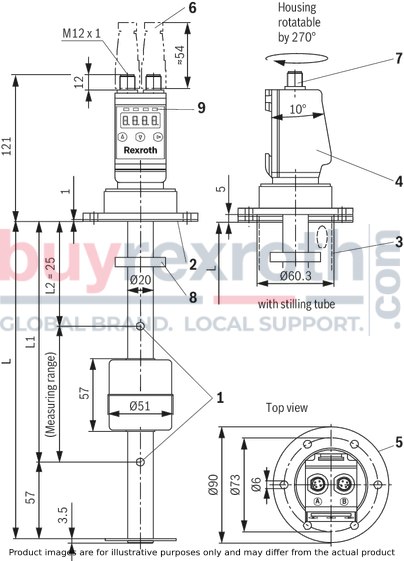

Dimensions: Float switch with display and control unit (version D..)

Dimensions in mm

|

1 |

Measuring range 4 … 20 mA |

|

2 |

Flat seal |

|

3 |

Stilling tube from L = 500 mm |

|

4 |

Name plate |

|

5 |

Installation opening of the tank |

|

6 |

Mating connector for plug-in connections K24 (M12 x 1), see table "Mating connector" |

|

7 |

Connector K24; 4-pole M12 x 1 |

|

8 |

Stroke limitation ring set to 20 mA (Type RTA) |

|

9 |

LEDs for the display of alarm switching points |

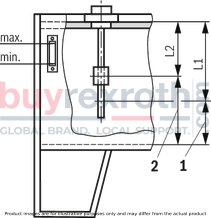

Oil volume specification for float switch

Type M with two switching contacts

|

1 |

Residual quantity with switching point L1 |

|

2 |

Residual quantity with switching point L2 |

|

Float switch Ordering length "L" |

Switching points pre-set |

Residual hydraulic fluid volume at switching point |

|||

|

|

|

AB 40-40, AB 40-43, AB 40-44 |

|||

|

L1 |

L2 |

NG |

L1 |

L2 |

|

|

mm |

mm |

mm |

l |

l |

|

| 370 | 220 | 140 | 63 | 28 | 42 |

| 220 | 140 | 100 | 45 | 67 | |

| 220 | 140 | 160 | 74 | 100 | |

| 220 | 140 | 250 | 120 | 174 | |

| 220 | 140 | 400 | 190 | 277 | |

| 220 | 140 | 630 | 365 | 475 | |

| 220 | 140 | 800 | 460 | 600 | |

| 500 | 280 | 160 | 1000 | 490 | 740 |

| 280 | 160 | 1250 | 780 | 1030 | |

| 280 | 160 | 1600 | 990 | 1310 | |

| 280 | 160 | 2000 | 1380 | 1730 | |

Attention!

Before the commissioning, the switching contacts are to be set according to the necessary operating conditions.

Adjustment of the switching height

The contacts installed in the float switch are screwed to a contact strip within the sliding tube. They are set to the switching points according to the preceding table and can be adjusted to higher or lower values retroactively (observe minimum distances!). For adjusting the contacts, proceed as follows:

Interrupt the voltage supply Loosen the plug-in connection Loosen the screws of the connector base and pull out the connector base with the contact strip Loosen the contact from the strip and fasten it at the desired position (it can be adjusted in steps of 10 mm) Carefully insert the contact strip Fasten the connector base by means of the screws Re-establish the plug-in connection and the power connectionType RTA, D1 and D2

in tank according to AB 40-40, AB 40-43 and AB 40-44

Tank size DN100 to 800

Dimensions in mm

Tank size DN1000 to 2000

Dimensions in mm

Installation opening of the tank cover

Dimensions in mm

Standard breakthrough AB 03-39.73 similar to DIN 24557 part 2

Fastening screws:

6 HEXAGONSOCKET HEAD CAP SCREWS ISO4762-M5X18-8.8-A2P; Material no. R900202612

Assembly information

Vertical installation according to technical data (see "Technical Data") Avoid flows Do not expose the switch to strong impact and bends Avoid external magnetic fields. They may impair the function of the reed contacts.

Electrical connections:

Electrical connections may only be performed by specialists Before performing any works at electrical parts, the voltage supply is to be interrupted Tighten round connector M12 x 1 or mating connectors after connection Only plug in the round connector M12 x 1 or mating connector if it is de-energized Do not overload the contacts (see technical data) In case of inductive load, provide for a protective circuit!Normative reference

AB 24-02

Cable sets and distributors

AB 40-40

Tank made of steel, form AN, cover form C, oil pan according to WHG

AB 40-43

Tank made of steel, cover form C

AB 40-44

Tank made of steel, with frame

R.08006

Mating connectors for controlling electric valves and sensors

DIN 24320

Flame-resistant fluids - Hydraulic fluids of categories HFAE and HFAS - Properties and requirements

DIN 51524

Hydraulic fluids; hydraulic oils

DIN EN 175201-804

Detail specification - Circular connectors - Round contacts, size diameter 1.6mm, threaded coupling; German version EN 175201-804:1999

DIN EN 175301-803

Detail specification: Rectangular connectors - Flat contacts, 0,8mm thickness, locking screw not detachable; German version EN 175301-803:1999

DIN EN 60751

Industrial platinum resistance thermometers and platinum temperature sensors (IEC 60751:2008)

DIN EN 60529

Protection classes by housing

VDMA 24317

Fluid technology – Flame-resistant fluids – Technical minimum requirements

VDMA 24568

Fluid technology – Fast bio-degradable fluids – Technical minimum requirements

VDMA 24574-1

Fluid technology – Terms, menu navigation and electrical connection for fluid sensors

Mating connectors

|

For detailed information see data sheet 08006 |

|||

|

Mating connector for connector K14 according to DIN EN 175301-803 |

Mating connector for connector K6 according to DIN EN 175201-804 |

||

|

Denomination |

Part number |

Denomination |

Part number |

|

LEITUNGSDOSE 4P Z14 M SW SPEZ |

R901017012 |

LEITUNGSDOSE 7P Z6 N6RFFK |

R900002803 |

|

|

|||

|

Mating connector for connector K24 |

Mating connector for connector K24 with potted-in PVC cable, 3 m long |

||

|

Denomination |

Part number |

Denomination |

Part number |

|

LEITUNGSDOSE 4P Z24 SPEZ |

R900031155 |

LEITUNGSDOSE 4P Z24M12X1+3MSPEZ |

R900064381 |

Mating connectors for mechanical pressure switches with connector “K14”, without circuitry, standard

4P Z14

Mating connectors for mechanical pressure switches with connector “K14”, without circuitry, standard

4P Z14

For mechanical pressure switches with connector “K14”, according to EN 175301-803 and ISO 4400, 3-pole + PE, “large cubic connector”Data sheet

Spare parts & repair

Mating connectors for sensors and valves with connector “K24”, “K35” and “K72”, M12 x 1

4P Z24

Mating connectors for sensors and valves with connector “K24”, “K35” and “K72”, M12 x 1

4P Z24

For sensors and valves with connector “K24”, “K35” and “K72” Mating connectors M12, 4-pole, line cross-section 0.75 mm2Data sheet

Spare parts & repair

Mating connectors for sensors and valves with connector “K24”, “K35” and “K72”, M12 x 1, with assembled connection line

4P Z24 +

Mating connectors for sensors and valves with connector “K24”, “K35” and “K72”, M12 x 1, with assembled connection line

4P Z24 +

For sensors and valves with connector “K24”, “K35” and “K72” Mating connectors M12, 4-pole, line cross-section 0.75 mm2Data sheet

Spare parts & repair

Mating connectors for mechanical position switches, mechanical pressure switches and valves with central connection with connector “K6” and “DK6L”, 6-pole + PE

7P Z6

Mating connectors for mechanical position switches, mechanical pressure switches and valves with central connection with connector “K6” and “DK6L”, 6-pole + PE

7P Z6

Mating connectors for mechanical position switches, mechanical pressure switches and valves with central connection with connector “K6”Data sheet

Spare parts & repair

Use in explosive areas according to directive 94/9/EC (ATEX)

The float switches ABZMS-41 are not suitable for the use in explosive areas.

Related Products

R901501106

$4,968.00 USD

R901500069

$4,425.00 USD

R901543195

$5,345.00 USD

R901500129

$4,987.00 USD

R901531777

$4,488.00 USD