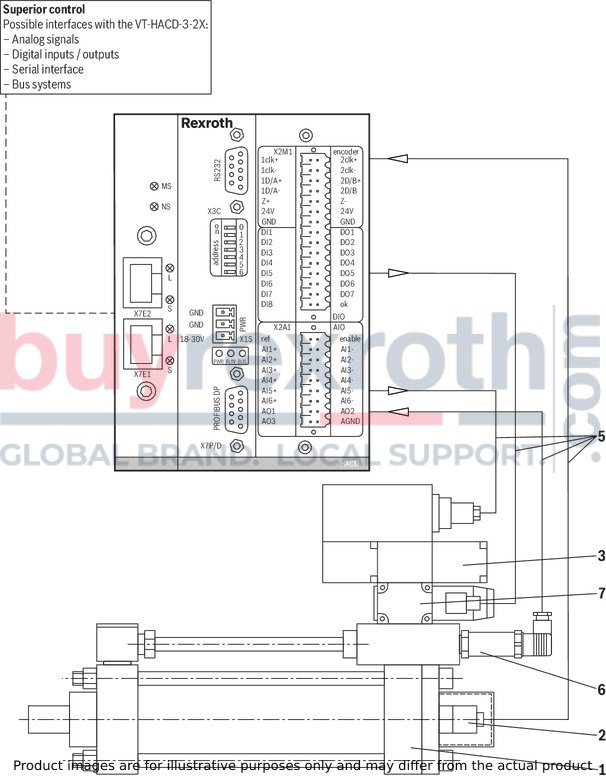

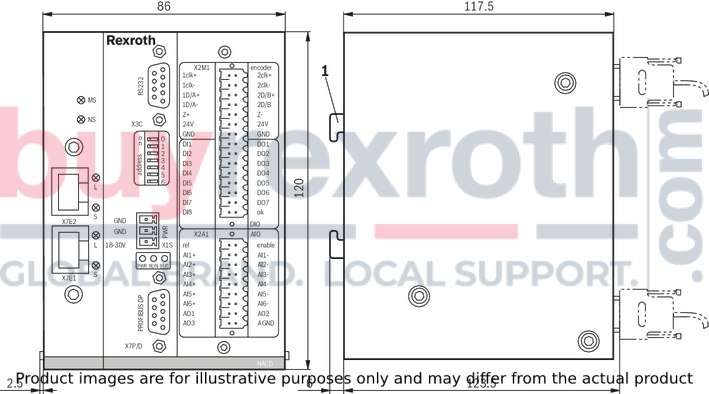

The VT-HACD-3-2X control electronics are a module for top hat rail mounting.

A microcontroller controls the entire process, makes adjustments, establishes connections and realizes the closed control loops. Data for configuration, command values and parameters are stored in a FLASH in a non-volatile form.

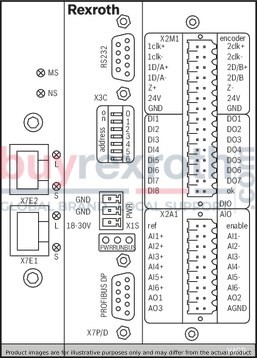

The BODAC PC program is used for the entire configuration and also for the parameterization and diagnosis. Besides the switches for address setting, the module is not equipped with any additional hardware switches. For the configuration, the HACD has to be connected to a PC via a serial interface (RS 232, 1:1 cable).

The configuration and thus the creation of applications are very simple - simply connect the pre-defined functional components. For this purpose, no programming knowledge is necessary.

A mode is available:

Structural editor

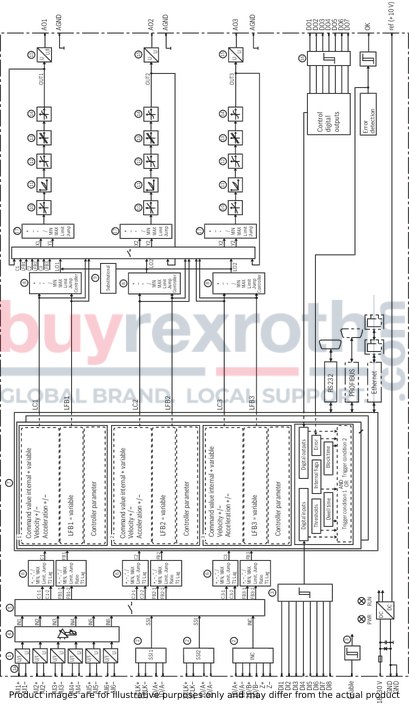

Own motion sequences can be established. For this purpose, 32 blocks are available.

Each block contains: Command value, ramp times, (velocity ±, acceleration ±) and controller parameters.

Blocks are activated by setting trigger conditions: Setting digital inputs, comparing signals with freely definable thresholds or expiry of waiting times.

Signal linking [6] [8] [17]

The HACD has various signal linking options both for the input and the output side, whereas 2 signals each can be linked. These are functions such as addition, subtraction, multiplication, division as well as minimum/maximum value generator, area ration and limiter:

+ = Addition: Z = X + Y

– = Subtraction: Z = X – Y

* = Multiplication: Z = X * Y / 100

/ = Division: Z = X / Y * 100

MIN = Minimum value generator: Z = MIN (X, Y)

MAX = Maximum value generator: Z = MAX (X, Y)

RATIO = Ratio input:

for RATIO >1: Z = X * RATIO – Y

for RATIO <1: Z = X – Y / RATIO

(e.g. area ratio for pressure differential measurement)

LIMIT = Signal limiter: Z = MIN (|X|, |Y|) * sign (X)

JUMP = Jump generator: Z = MAX (|X|, |Y|) * sign (X)

with Z … result

X … 1st signal

Y … 2nd signal

T1 Lag = Low pass filter

Analog I/O [1] [15]

The 6 analog inputs are switchable between ±10 V, 0…10 V, 0…20 mA by means of the software.

The analog output AO1 is switchable between ±10 V, 0…10 V, 0…20 mA and 4…20 mA by means of the software.

AO2 and AO3 are fixedly set to ±10 V.

The output is switched so that the whole range of the analog-digital converter is used.

Both working range and error detection can be defined for all analog inputs.

The analog outputs can be adjusted by means of amplification and offset.

Digital I/O [3] [16]

The HACD has 9 digital inputs and 8 digital outputs.

An input has the fix functionality Enable, a digital output the fixed functionality OK.

Further digital inputs are used for the triggering of blocks (see blocks and triggering).

The function of each digital output can be determined by the selection from a predefined list:

Command value = actual value Actual value higher or lower than the adjustable threshold Waiting time completed Ramp active internal flag set Error flag set Table completed Error status Block timeout Controller active Absolute value (actual value) < window Absolute value (command value) < window Incremental home position

Digital position measurement system

If VT-HACD-3-2X is used as control electronics, digital position measurement systems of type SSI or incremental can be used for actual value recording.

Limitations of use for the incremental encoder

The maximum frequency of the HACD incremental encoder input (fG) is 250 kHz. The maximum travel velocity of the drive, the resolution (res) of the encoder system used and the possible signal evaluation by EXE (interpolation and digitalizing electronics) determine the frequency.

Determination formulas

Encoder resolution at given maximum velocity:

Velocity at specified encoder resolution:

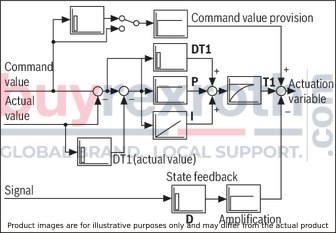

Controller

If the HACD is used as control electronics, select "Controller" for signal linking [8].

The LCx signals indicate the command value branch, the LFBx signals indicate the actual value branch. [8]

Both SSI encoder or incremental encoder [2] (digital measurement system) and one or more analog sensors can be used as actual value signal.

The controller structure is designed as PIDT1 controller, whereas each share can be activated or deactivated individually. Thus, also a P or PT1 controller can be implemented for example. The I share can additionally be controlled via a window (upper and lower limit).

Control parameters can be set in blocks or independently of blocks.

A state feedback can be used for controller output damping.

Controller structure:

Adjustment to hydraulic system

For the optimum adjustment to the particularities of hydraulic drives, the following functions are implemented upstream the analog output:

Direction-dependent amplification [10]

For positive and negative values, the amplification can be set separately. In this way, adjustment to the area ratio of a differential cylinder is possible.

Characteristic curve correction [11]

In this way, the progressive flow characteristics of proportional directional valves are compensated or an inflected characteristic curve is realized.

Overlap jump/residual velocity [12]

When using valves with positive overlap, a fine positioning can be used in case of a PDT1 controller in order to increase the static accuracy. This fine positioning can be selected according to the residual voltage principle and as overlap jump.

Zero point correction (offset) [13]

Serves the correction of the zero point of the connected proportional servo valve.

Error detection and treatment

The HACD supports numerous error monitoring possibilities:

Monitoring of analog inputs for lower deviation or exceeding of the range Monitoring the sensor technology for cable break Control error monitoring when configuring the HACD as controller Monitoring of the supply voltage, any internal

voltage as well as the ±10 V reference voltage

Monitoring the microcontroller (watchdog) as well as the memory (checksum). The error monitoring as well as its reaction can be configured as well.

[ ] = Assignment to the block diagram