***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

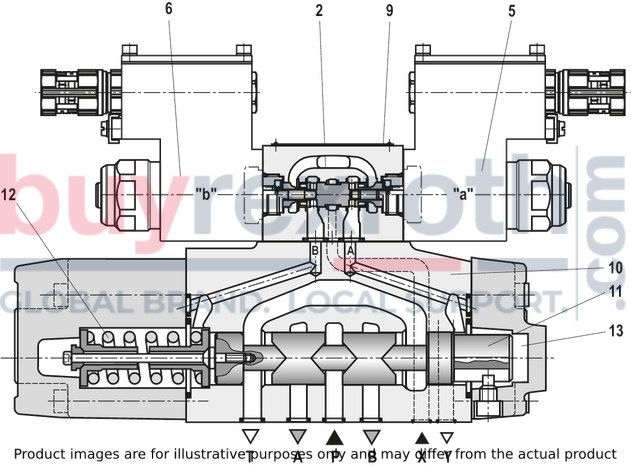

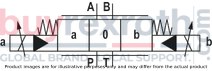

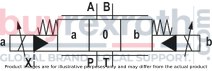

The Bosch Rexroth 4WRZ32W6-520-7X/6EG24XEJ/D3V (R901149529) is a sophisticated pilot-operated proportional directional control valve designed for precision hydraulic flow control. This valve integrates a type DREP pilot control valve, which functions as a pressure reducing valve, modulating pressure based on the electrical input signal received from proportional solenoids. The 4WRZ32W6-520-7X/6EG24XEJ/D3V features wet-pin DC solenoids that are externally controlled and offers users the capability to finely tune hydraulic operations through its responsive solenoid actuation.

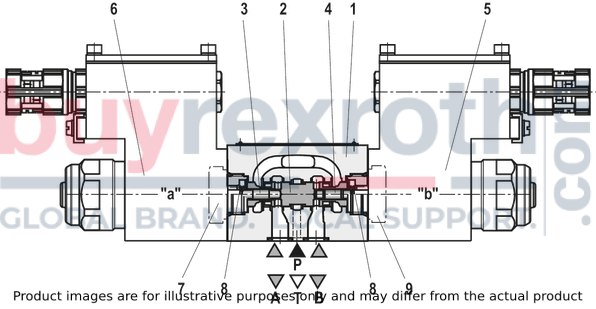

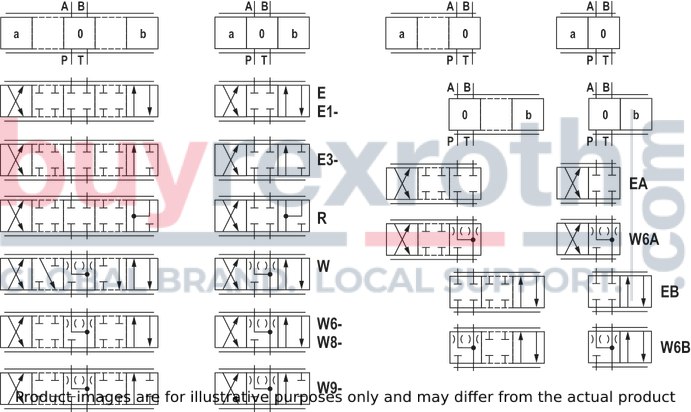

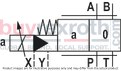

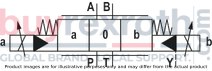

The unit is constructed with a robust housing that includes a control spool with pressure measuring pins and central thread. When the solenoids are deenergized, the compression springs hold the control spool in a central position, allowing free flow of hydraulic fluid to the tank. Actuation of a proportional solenoid adjusts the control spool, regulating the connection between ports and maintaining set pressure levels proportionally to the current supplied to the solenoid.

This model presents two spool positions and comes in versions DREPA and DREPB, each equipped with one solenoid (A or B), simplifying its operation. The main valve comprises a main control spool and centering spring, which are proportionally controlled by the pilot valve to manage flow direction and size.

Notably designed for use in potentially explosive atmospheres, this size 32 valve adheres to ISO standards for porting patterns and is suitable for subplate mounting. It boasts an impressive maximum operating pressure of 350 bar and can handle maximum flow rates up to 1200 l/min. The explosion protection compliance ensures its application within hazardous environments according to EU Directive IIG with Ex eb mb IIC T4 Gb protection for its solenoids as per EN standards.

In summary, Bosch Rexroth's 4WRZ32W6-520-7X/6EG24XEJ/D3V offers precise hydraulic control in demanding applications where reliability and safety in explosive environments are paramount.

$36,809.00 USD

More are expected on October 1, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $35,888.77 USD | $920.23 USD |

| 25+ | $34,968.55 USD | $1,840.45 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as October 1, 2026 when ordered in