***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

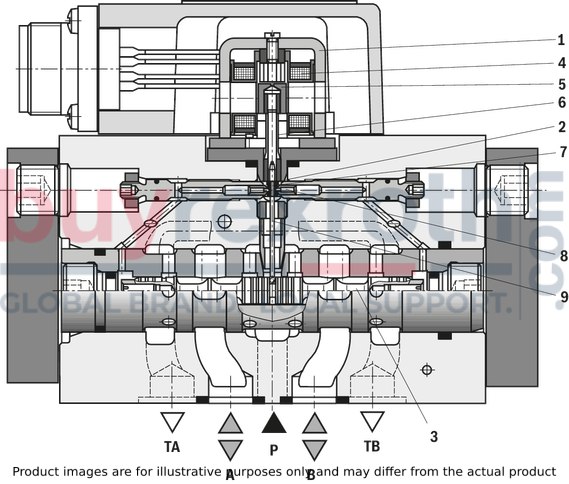

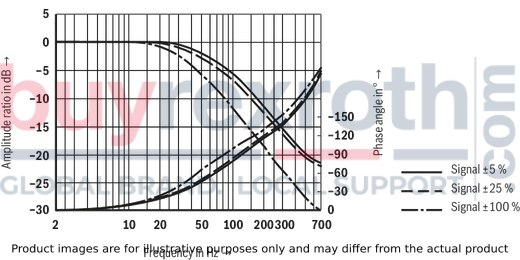

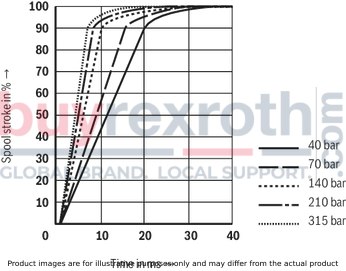

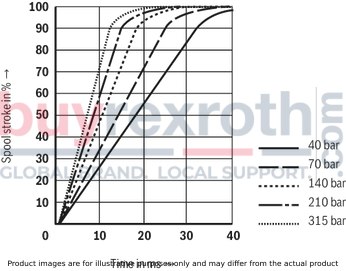

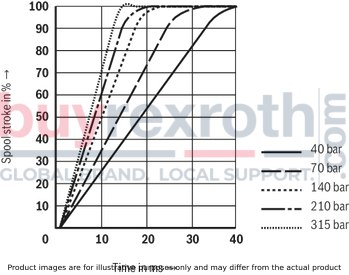

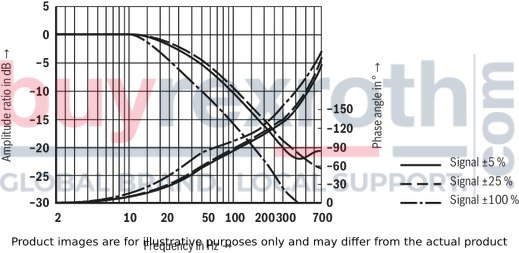

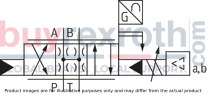

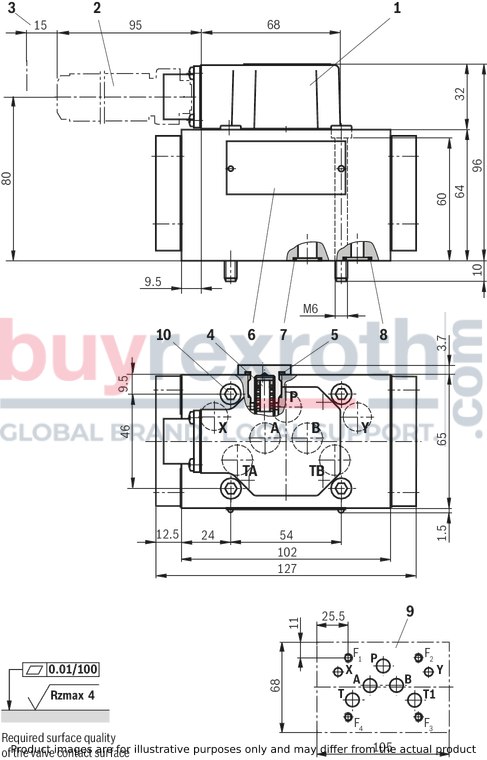

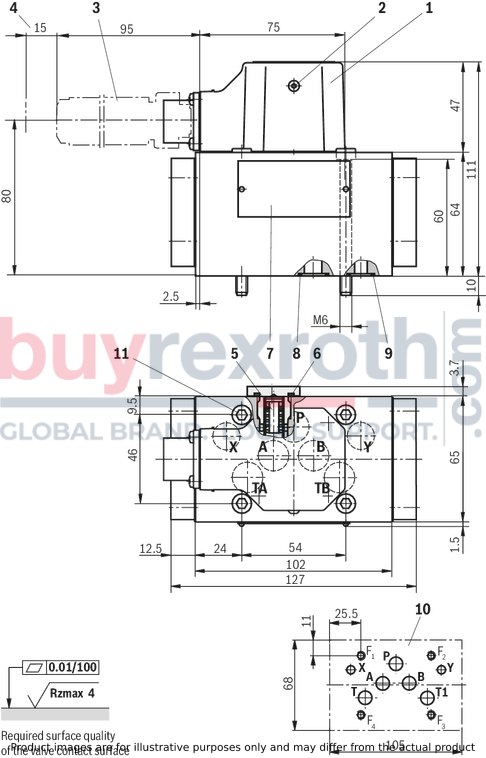

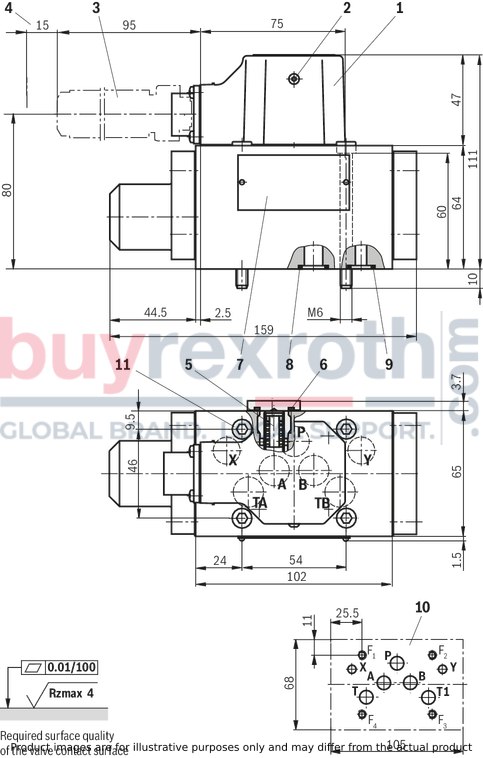

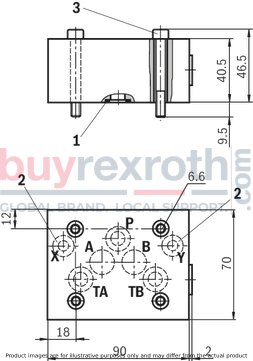

The Bosch Rexroth 4WSE2EM10-5X/75B9ET315K31EV (R900949289) is a highly sophisticated electrically operated, stage directional servo valve designed for precision control of position, force, and velocity in hydraulic systems. This valve incorporates a torque motor, a nozzle flapper plate amplifier, and a control spool within a sleeve to achieve precise manipulation of hydraulic flow. The torque motor is actuated by an electrical input signal which, with the help of a permanent magnet, generates force on the armature. This action results in movement of the flapper plate, creating a pressure differential that moves the control spool to regulate the connection between pressure ports and actuator ports.

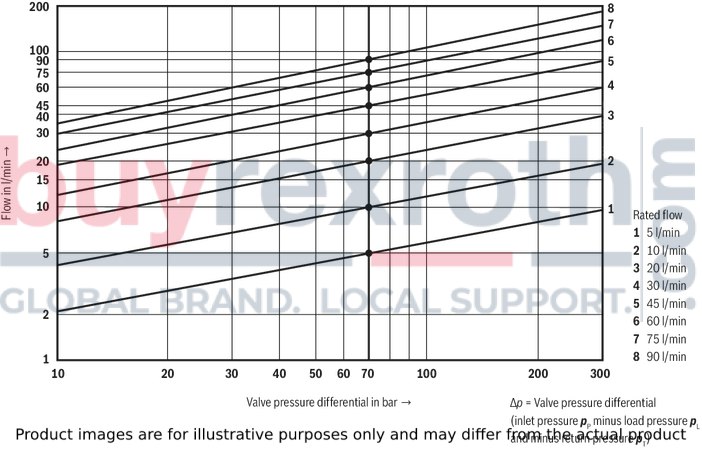

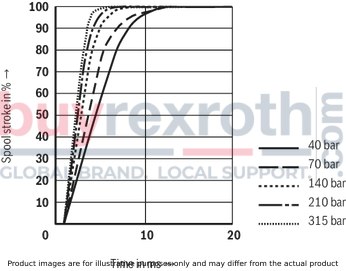

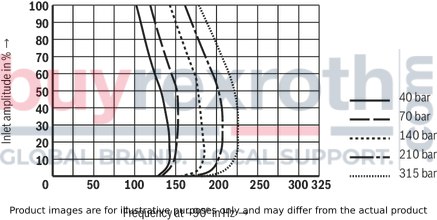

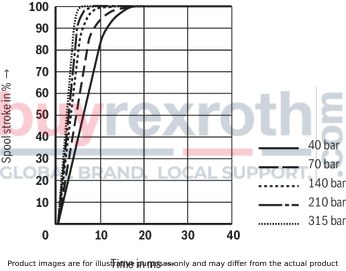

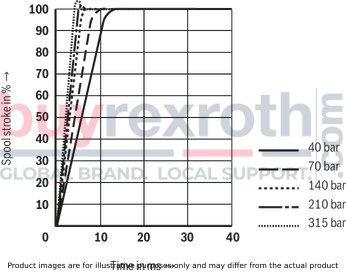

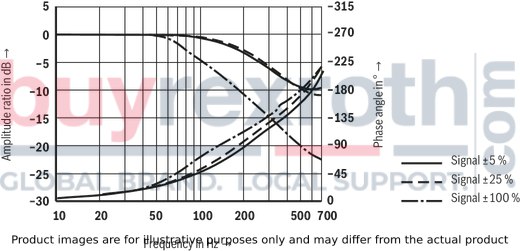

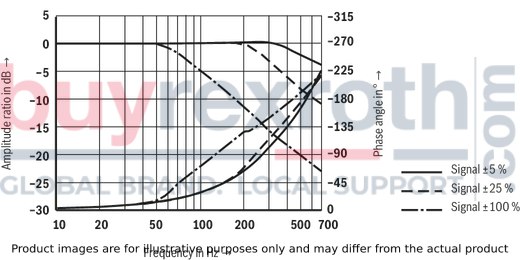

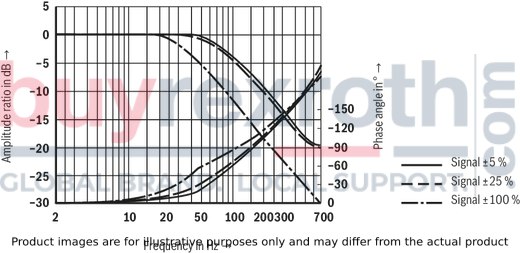

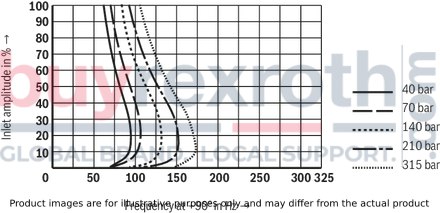

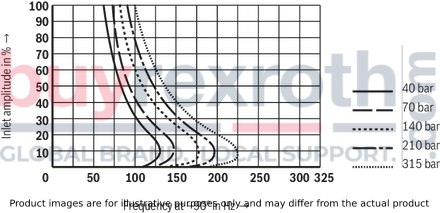

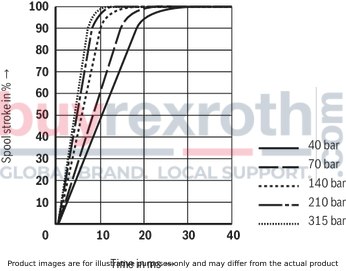

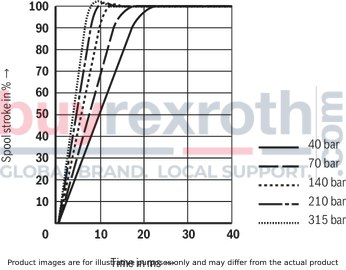

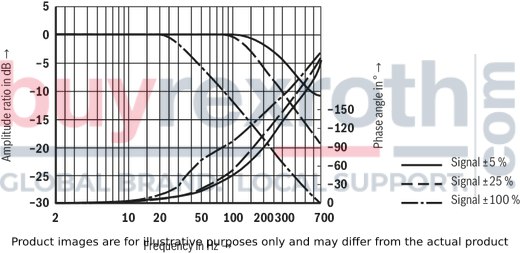

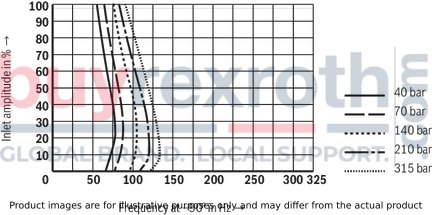

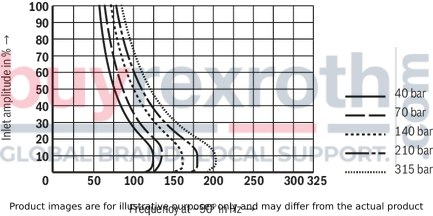

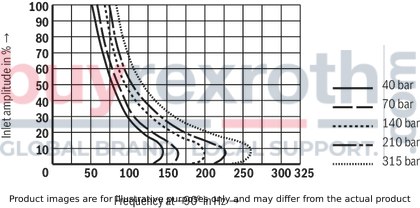

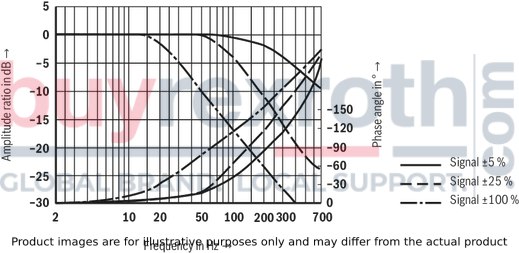

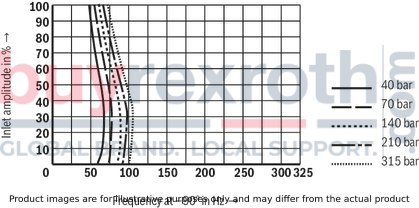

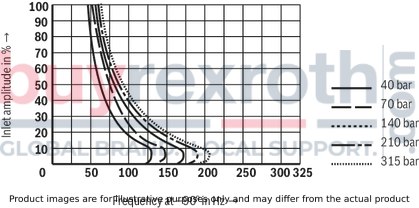

The unique mechanical feedback system through a bending spring ensures that the position of the control spool is adjusted until equilibrium is reached between feedback torque and electromagnetic torque. This balance maintains zero pressure differential at the nozzle flapper plate system. The servo valve's flow rate is proportional to the electrical input signal but also depends on the valve's pressure drop.

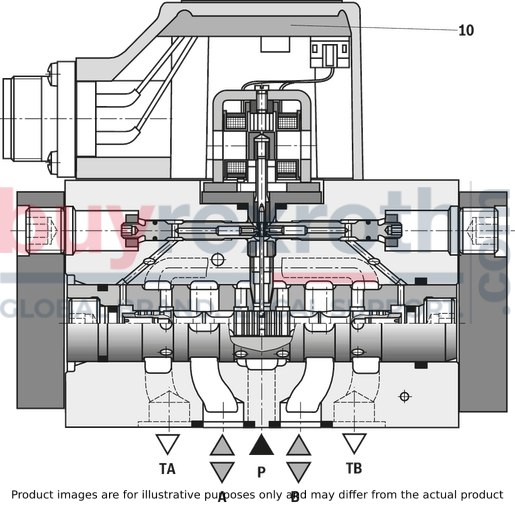

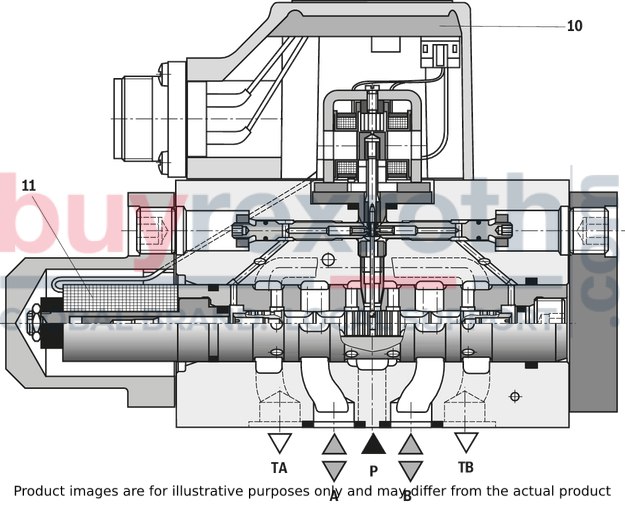

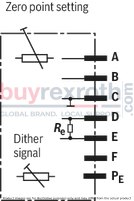

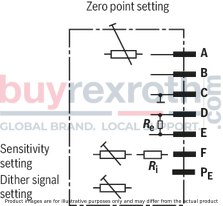

For this model, integrated control electronics are mandatory for operation. These electronics amplify analog input signals for precise valve actuation and include an externally accessible potentiometer for zero-point adjustments. It should be noted that only trained specialists should implement changes to the zero point to prevent potential system damage.

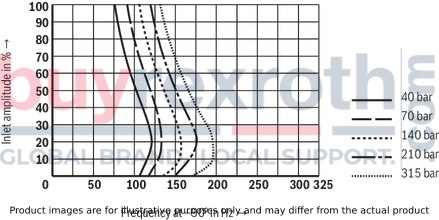

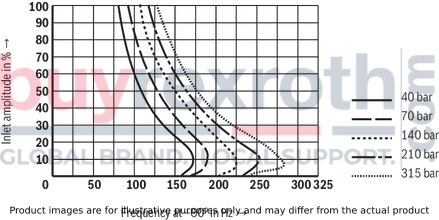

Key features of this Bosch Rexroth servo valve include its suitability for subplate mounting with an ISO pattern, dry control motor preventing contamination from hydraulic fluid, wear-free control spool return element options, and external or integrated electronic controls. The unit is meticulously adjusted and tested to ensure optimal performance. Additionally, it offers flow force compensation and reduced susceptibility to temperature and pressure variations due to its centrically fixed control sleeve design. The maximum operating pressure is rated at bar with a maximum flow rate of l/min. A filter accessible from outside ensures easy maintenance for long-lasting operation and reliability.

$10,835.00 USD

More are expected on September 17, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as September 17, 2026 when ordered in