***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth 4WRSEH6V12LD-3X/G24K0/A1V-280 (R900618927) is a high-response directional control valve with integrated control electronics, designed for direct operation through its solenoids. This state-of-the-art valve is engineered to regulate flow direction and magnitude with precision, making it an exceptional choice for applications involving position, velocity, and pressure control. The valve's standout features include electrical position feedback, high response sensitivity, and low hysteresis, which contribute to its reliable performance and efficiency in various control tasks.

Built for subplate mounting, the 4WRSEH6V12LD-3X/G24K0/A1V-280 adheres to DIN form A and ISO standards regarding porting patterns. Its robust design incorporates a housing with a connection surface, a control spool within a sleeve supported by compression springs, solenoids with coverings, a position transducer, and accessible integrated control electronics that facilitate zero-point adjustment.

Functionally, this valve operates by shifting the control spool proportionally to the electric input signal. This allows for smooth transitions from P to A and B to T through orifice-type cross-sections that exhibit continuous or inflected linear flow characteristics. In instances where the solenoid is deenergized, the compression spring ensures that the control spool reverts to a failsafe position—a critical safety feature for system integrity.

The Bosch Rexroth 4WRSEH6V12LD-3X/G24K0/A1V-280 valve is characterized by its direct operated plate design which enables it to respond rapidly and accurately to electronic commands while maintaining stability even when the solenoid is switched off. It boasts specifications including a maximum operating pressure of up to 280 bar and nominal flow rates that cater to demanding hydraulic applications requiring precise flow modulation under varying conditions.

This product is not available. CLICK HERE to create a support ticket for us to locate your part or a suitable replacement

This product is eligible for factory repair.

Direct operated high-response directional valve with integrated control electronics (OBE) for the control of flow direction and size Suitable for position, velocity and pressure control purposes Operation by means of control solenoids Electrical position feedback High response sensitivity and low hysteresis Integrated electronics (OBE) For subplate mounting: Porting pattern according to DIN 24340 form A and ISO 4401 With Fail-safe position for 4/4-directional control valve

4/4 directional design

In principle, the function of these valves corresponds to the function of the 4/3-way version. With de-energized solenoid, the control spool is, however, held in a fail-safe position by a compression spring.

The 4/4 directional control valves are designed as direct operated devices in plate design. Operation is effected by means of control solenoid. The solenoid is controlled via integrated control electronics.

Set-up:

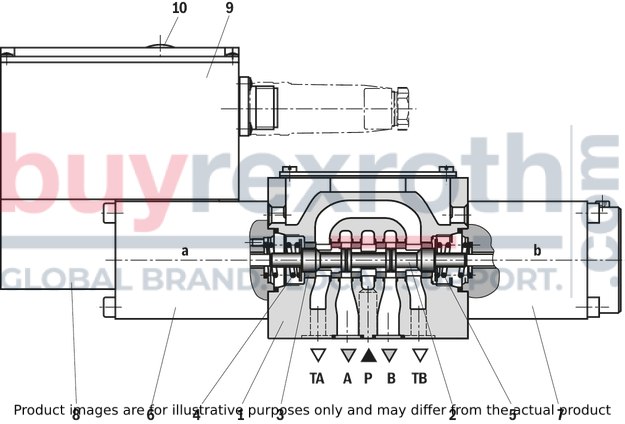

The valve basically consists of:

Housing (1) with connection surface Control spool (2) in sleeve (3) with compression springs (4) Solenoid (5) and cover (6) Position transducer (7) Integrated control electronics (8) Zero point adjustment accessible via Pg9 (9)

Functional description:

With de-energized solenoid (5), fail-safe position of the control spool (2) by compression spring (4) Direct operation of the control spool (2) by energization of a control solenoid (5)e.g. control of the solenoid

Displacement of the control spool (2) proportionally to the electric input signal Connection from P to A and B to T via orifice-type cross-sections with continuous or inflected linear flow characteristicsSwitching off the solenoid (5) The compression spring (4) brings the control spool (2) back into the fail-safe position

The 4/3 and 4/4 directional control valves are designed as direct operated devices in plate design. Operation is effected by means of control solenoids. The solenoids are controlled via integrated control electronics.

Set-up:

The valve basically consists of:

Housing (1) with connection surface Control spool (2) in sleeve (3) with compression springs (4 and 5) Solenoids (6 and 7) Position transducer (8) Integrated control electronics (9) Zero point adjustment (10) accessible via Pg9

Functional description:

4/3 directional design

With de-energized solenoids (6 and 7), mechanical central position of the control spool (2) by compression springs (4 and 5) Direct operation of the control spool (2) by energization of a control solenoide.g. control solenoid "b" (7)

Displacement of the control spool (2) to the left, proportionally to the electric input signal Connection from P to A and B to T via orifice-type cross-sections with continuous or inflected linear flow characteristics Switching off the solenoid (7) The compression spring (4) brings the control spool (2) back into the central position

In the de-energized condition, the control spool (2) is held in a mechanical central position by the control springs. This position does not correspond to the hydraulic central position!

When the electric valve control loop is closed and with command value presetting 0 (0 V with A1 and/or 12 mA with F1), the control spool (2) is positioned in the hydraulic central position.

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

|||

|

4WRS |

E |

H |

‒ |

3X |

/ |

G24 |

K0 |

/ |

V |

* |

|

01 |

High-response directional valves, direct operated, with electrical position feedback |

4WRS |

|

02 |

With integrated control electronics |

E |

|

03 |

Control spool/sleeve |

H |

|

04 |

Size 6 |

6 |

|

Size 10 |

10 |

|

|

Symbols; for the possible version, see "Symbols/Circuit diagrams" |

||

|

05 |

4/3-way version |

V |

|

4/4 directional design |

C3, C4 |

|

|

Installation side of the inductive position transducer with control spool symbol “V” |

||

|

06 |

4WRSEH.V...-3X/...

|

no code |

4WRSEH.VC...-3X/...

|

C |

|

|

Installation side of the inductive position transducer with control spool symbol “C3” and “C4” |

||

|

06 |

4WRSEH.C.B...-3X/...

|

B |

4WRSEH.C...-3X/...

|

no code |

|

|

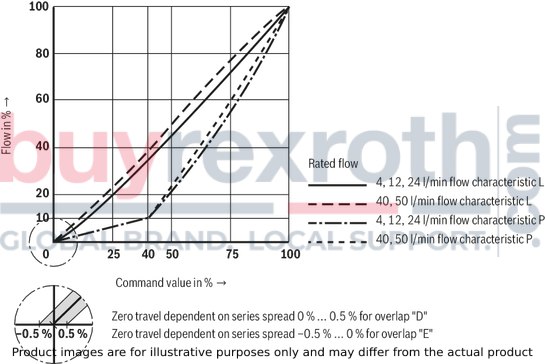

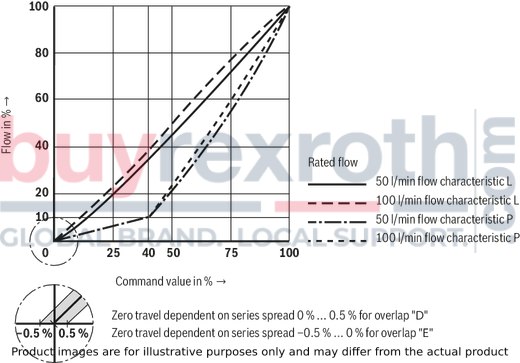

Rated flow at 70 bar valve pressure differential |

||

|

07 |

Size 6 |

|

|

4l/min |

04 1) |

|

|

12 l/min |

12 |

|

|

24 l/min |

24 |

|

|

40 l/min |

40 2) |

|

|

50 l/min |

50 3) |

|

|

Size 10 |

||

|

50 l/min |

50 |

|

|

100 l/min |

100 |

|

|

Flow characteristic |

||

|

08 |

Linear |

L |

|

Inflected characteristic curve 40% |

P |

|

|

Control spool overlap |

||

|

09 |

0 ... 0,5% negativ |

E 4) |

|

0 ... 0,5 % positiv |

D 4) |

|

|

10 |

Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions) |

3X |

|

Supply voltage of the control electronics |

||

|

11 |

Direct voltage 24 V |

G24 |

|

Electrical connection |

||

|

12 |

Without mating connector, with connector according to E DIN 43 563-MA6, separate order |

K0 |

|

Electrical interface |

||

|

13 |

Command value input ±10 VDC |

A1 |

|

Command value input 4 ... 20 mA |

F1 |

|

|

Seal material |

||

|

14 |

FKM seals |

V |

|

15 |

Further details in the plain text |

* |

|

1) |

Use only in connection with flow characteristics "L" |

|

|

2) |

Only with “C” and “V” in connection with flow characteristics "P" |

|

|

3) |

Only with “V” in connection with flow characteristics "L" |

|

|

4) |

The control spool overlap in % is referred to the nominal stroke of the control spool. We recommend the D overlap for control tasks. Other control spool overlaps upon request! |

|

For applications outside these parameters, please consult us!

general

|

Type |

4WRSEH | |||

|

Size |

6 | 10 | ||

|

Component series |

3X | |||

|

Installation position |

any, preferably horizontal | |||

|

Weight |

Valve with one solenoid |

kg |

2.3 | 6 |

|

Valve with two solenoids |

kg |

3 | 7.3 | |

|

Storage temperature range |

°C |

-20 … +80 | ||

|

Ambient temperature range |

°C |

-20 … +50 | ||

hydraulic

|

Type |

4WRSEH | |||

|

Size |

6 | 10 | ||

|

Maximum operating pressure |

bar |

315 | ||

|

Maximum operating pressure |

Port P |

bar |

315 | |

|

Port A |

bar |

315 | ||

|

Port B |

bar |

315 | ||

|

Port T |

bar |

315 | 210 | |

|

Maximum flow |

l/min |

80 | 180 | |

|

Nominal flow 1) |

l/min |

4 12 24 40 50 |

50 100 |

|

|

Hydraulic fluid temperature range |

°C |

-20 … +80 | ||

|

Viscosity range |

Maximum admissible |

mm²/s |

20 … 380 | |

|

Recommended |

mm²/s |

30 … 46 | ||

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 2) |

Class 18/16/13 according to ISO 4406 (c) | |||

|

Hysteresis |

% |

< 0.05 | ||

|

Response sensitivity |

% |

< 0.03 | ||

|

Range of inversion |

% |

< 0.03 | ||

| 1) | at 70 bar valve pressure differential |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

hydraulic

|

Nominal flow |

l/min |

50 | 100 | 4, 12 | 24 | 40 | |

|

Limitation of use |

Symbols C, C3, C5 |

bar |

250 | 150 | 315 | 160 | |

|

Symbols C1, C4 |

bar |

150 | 100 | 315 | 200 | 100 | |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

Mineral oils and related hydrocarbons |

HL, HLP |

NBR / FKM |

DIN 51524 |

|

Phosphoric acid esters |

HFD-R |

FKM |

|

|

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. |

|||

electrical

|

Type |

4WRSEH | ||

|

Size |

6 | 10 | |

|

Voltage type |

Direct voltage | ||

|

Type of signal |

analog | ||

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | ||

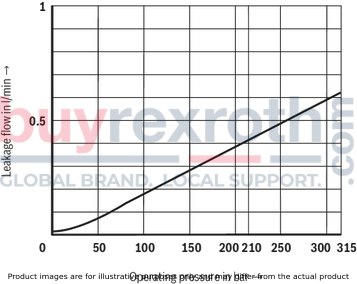

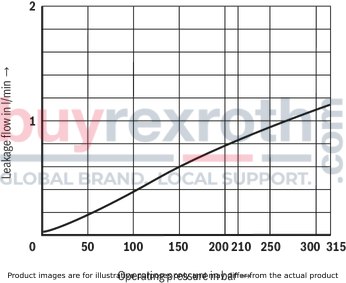

(measured with HLP46, ϑÖl = 40 ±5 °C)

Pressure-signal characteristic curve, ps = 100 bar4WRSEH 6...L....

NG6

Zero flow (typical)

NG6

Flow characteristic curve

NG6

Transition function4/3 directional design

NG6

Transition function 4/4 directional design

NG6

Frequency response 4/3 directional design

NG6

Frequency response 4/4 directional design

NG6

Flow/load function with maximum valve opening (tolerance ±10 %) (4/3 directional design)

NG6

Flow/load function with maximum valve opening (tolerance ±10 %) (4/4 directional design)

NG6

Pressure-signal characteristic curve, ps = 100 bar4WRSEH 10...L....

Size 10

Zero flow (typical)

Size 10

Flow characteristic curve

Size 10

Transition function4/3 directional design

Size 10

Transition function 4/4 directional design

Size 10

Frequency response 4/3 directional design

Size 10

Frequency response 4/4 directional design

Size 10

Flow/load function with maximum valve opening (tolerance ±10 %) (4/3 directional design)

Size 10

Flow/load function with maximum valve opening (tolerance ±10 %) (4/4 directional design)

Size 10

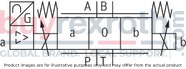

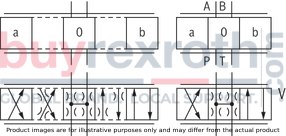

Symbols

4/3-way version

Symbols

4/4 directional design

4WRSEH.V...-3X/...

4WRSEH.VC...-3X/...

4WRSEH.C.B...-3X/...

4WRSEH.C...-3X/...

|

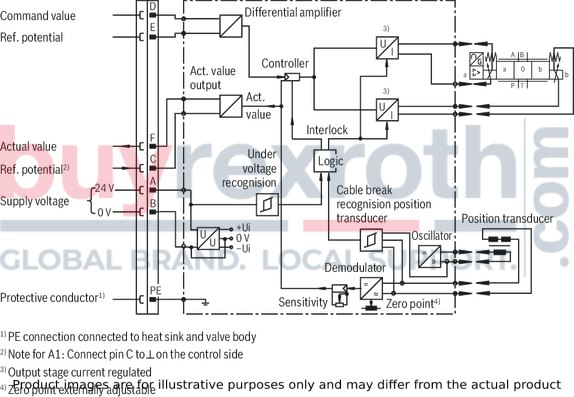

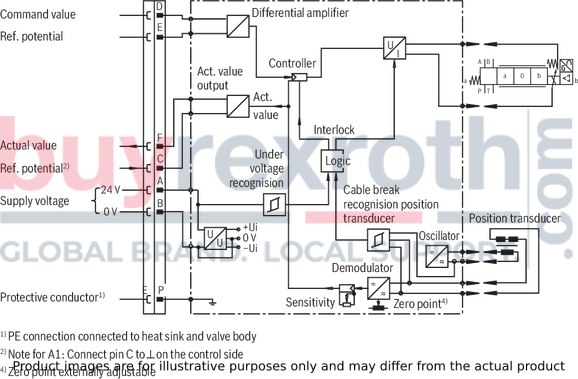

Pin assignment |

Contact |

Assignment interface "A1" |

Assignment interface "F1" |

|

Power supply |

A |

24 VDC (19,4 ... 35 VDC), Imax = 2 A (NG6), Imax = 2.8 A (NG10), impulse load: 4 A |

|

|

B |

0 V

|

||

|

Reference potential actual value |

C |

Reference potential for contact F; |

Reference potential for contact F |

|

Differential amplifier input (command value) |

D |

±10 V command value; Re > 50 kΩ |

4 ...20 mA command value; Re > 100 Ω |

|

E |

Reference potential for contact D |

||

|

Measuring output (actual value) |

F |

± 10 V; Imax = 2 mA |

4 ... 20 mA; load resistance maximum 500 Ω |

|

PE |

connected to cooling element and valve housing |

||

Command value: Positive command value (0...10 V or 12...20 mA) at D and reference potential at E result in flow from P → A and B → T.

Negative command value (0...-10 V or 12...4 mA) at D and reference potential at E result in flow from P → B and A → T.

Actual value: Positive signal (0...10 V or 12...20 mA) at F and reference potential at C result in flow from P → A.

Connection line: Recommendation:

up to 25 m line length: Type LiYCY 7 x 0.75 mm² up to 50 m line length: Type LiYCY 7 x 1.0 mm²External diameter 6.5 … 11 mm and/or 8 ... 13.5 mm

Connect shield to ⊥ only on the supply side.

4/3-way version

4/4 directional design

Notice:

Electrical signals provided via control electronics (e. g. actual value) must not be used to switch off safety-relevant machine functions. (See also the European standard "Safety requirements for fluid-powered systems and their components - Hydraulics", EN 982!)

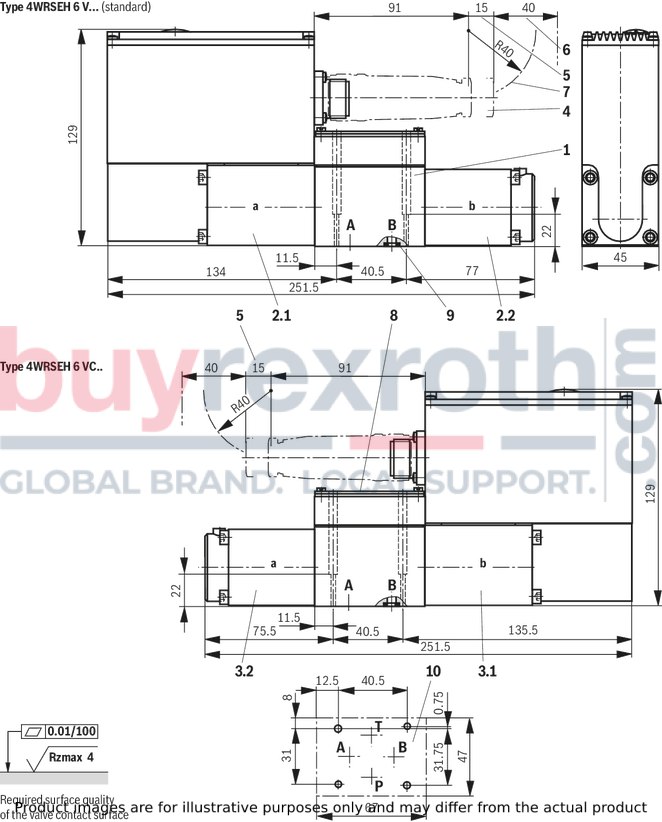

|

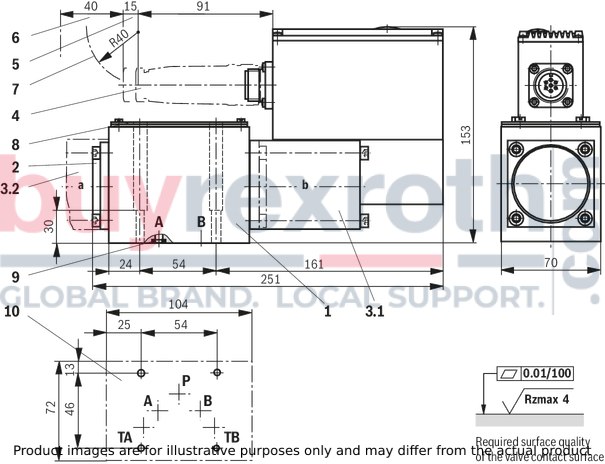

1 |

Valve housing |

|

2.1 |

Control solenoid "a" with inductive position transducer |

|

2.2 |

Control solenoid “b” |

|

3.1 |

Control solenoid "b" with inductive position transducer |

|

3.2 |

Control solenoid “a” |

|

4 |

Mating connector according to DIN EN 175201-804, separate order |

|

5 |

Space required to remove the mating connector |

|

6 |

Additional space required for bending radius of the connection line |

|

7 |

Cable bending radius |

|

8 |

Name plate |

|

9 |

Identical seal rings for ports A, B, P, and T |

|

10 |

Machined valve contact surface; Porting pattern according to DIN 24340-A6 and ISO 4401-03-02-0-05 |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M5 x 30 - 10.9-flZn-240h-L (Friction coefficient total = 0.09 ... 0.14)Tightening torque MA = 7 Nm ± 10 % , material no. R913000316

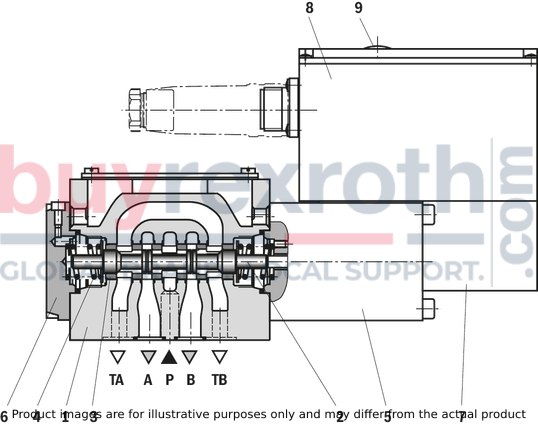

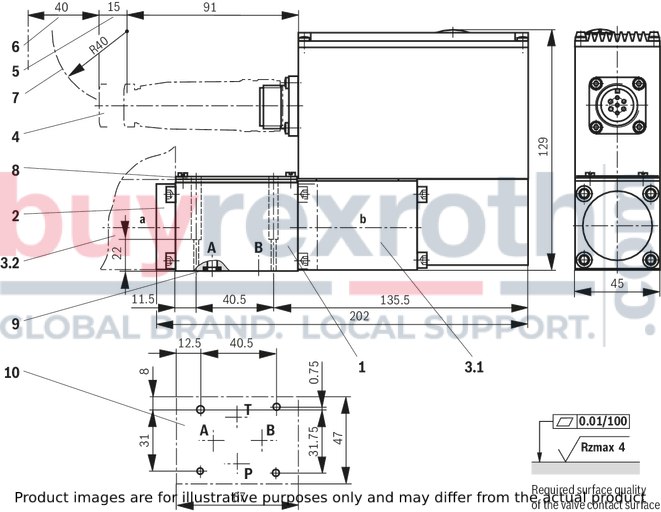

Typ 4WRSEH 6 C.B...

|

1 |

Valve housing |

|

2 |

Cover |

|

3.1 |

Control solenoid "b" with inductive position transducer |

|

3.2 |

Control solenoid "a" with inductive position transducer |

|

4 |

Mating connector according to DIN EN 175201-804, separate order |

|

5 |

Space required to remove the mating connector |

|

6 |

Additional space required for bending radius of the connection line |

|

7 |

Cable bending radius |

|

8 |

Name plate |

|

9 |

Identical seal rings for ports A, B, P, and T |

|

10 |

Machined valve contact surface; Porting pattern according to DIN 24340-A6 and ISO 4401-03-02-0-05 |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M5 x 30 - 10.9-flZn-240h-L (Friction coefficient total = 0.09 ... 0.14)Tightening torque MA = 7 Nm ± 10 % , material no. R913000316

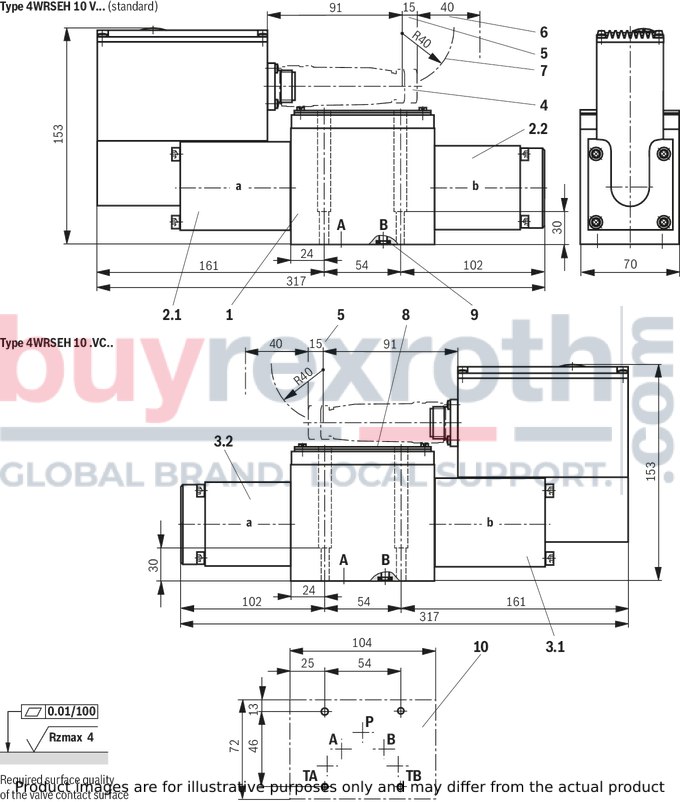

|

1 |

Valve housing |

|

2.1 |

Control solenoid "a" with inductive position transducer |

|

2.2 |

Control solenoid “b” |

|

3.1 |

Control solenoid "b" with inductive position transducer |

|

3.2 |

Control solenoid “a” |

|

4 |

Mating connector according to DIN EN 175201-804, separate order |

|

5 |

Space required to remove the mating connector |

|

6 |

Additional space required for bending radius of the connection line |

|

7 |

Cable bending radius |

|

8 |

Name plate |

|

9 |

Identical seal rings for ports A, B, P, and T |

|

10 |

Machined valve contact surface; Porting pattern according to DIN 24340-A10 and ISO 4401-05-05-0-05 |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M6 x 40 - 10.9-flZn-240h-L (Friction coefficient total = 0.09 ... 0.14)Tightening torque MA = 12.5 Nm ± 10 %, material no. R913000058

Typ 4WRSEH 10 C.B...

|

1 |

Valve housing |

|

2 |

Cover |

|

3.1 |

Control solenoid "b" with inductive position transducer |

|

3.2 |

Control solenoid "a" with inductive position transducer |

|

4 |

Mating connector according to DIN EN 175201-804, separate order |

|

5 |

Space required to remove the mating connector |

|

6 |

Additional space required for bending radius of the connection line |

|

7 |

Cable bending radius |

|

8 |

Name plate |

|

9 |

Identical seal rings for ports A, B, P, and T |

|

10 |

Machined valve contact surface; Porting pattern according to DIN 24340-A10 and ISO 4401-05-05-0-05 |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M6 x 40 - 10.9-flZn-240h-L (Friction coefficient total = 0.09 ... 0.14)Tightening torque MA = 12.5 Nm ± 10 %, material no. R913000058

Mating connectors for valves with round connector, 6-pole + PE

7P Z31

Mating connectors for valves with round connector, 6-pole + PE

7P Z31

For valves with round connector according to EN 175201-804, 6-pole + PE as well as 6-pole, compatible with VG 95328Data sheet

Spare parts & repair

Related Products

R901364865

$5,568.00 USD

R900738737

$11,151.00 USD

R900925484

$3,931.00 USD

R900617766

$3,181.00 USD

R900967209

$1,911.00 USD

R901364865

$5,568.00 USD

R900738737

$11,151.00 USD

R900925484

$3,931.00 USD

R900617766

$3,181.00 USD

R900967209

$1,911.00 USD

R901364865

$5,568.00 USD

R900738737

$11,151.00 USD

R900925484

$3,931.00 USD