***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

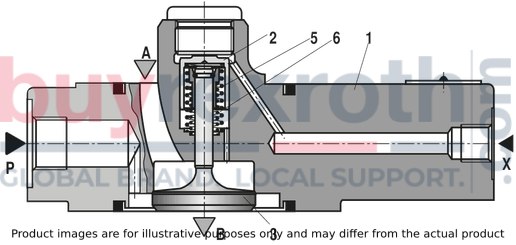

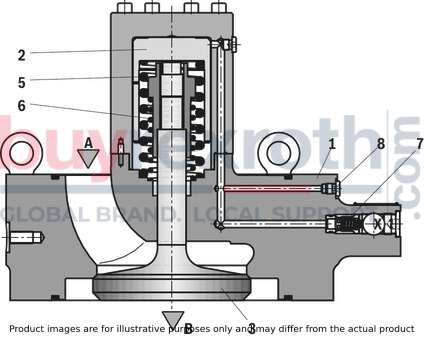

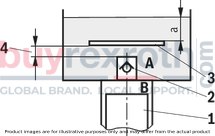

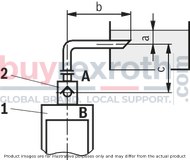

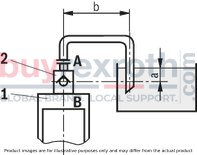

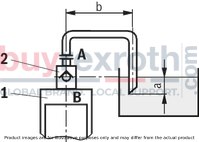

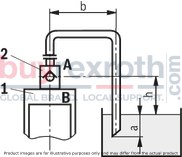

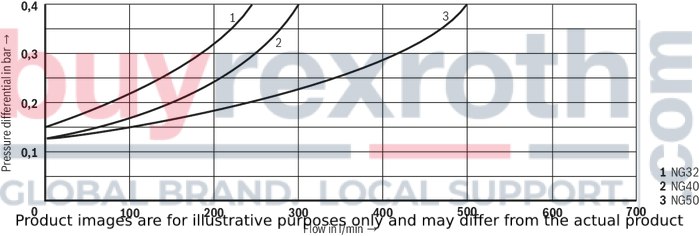

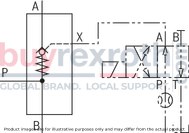

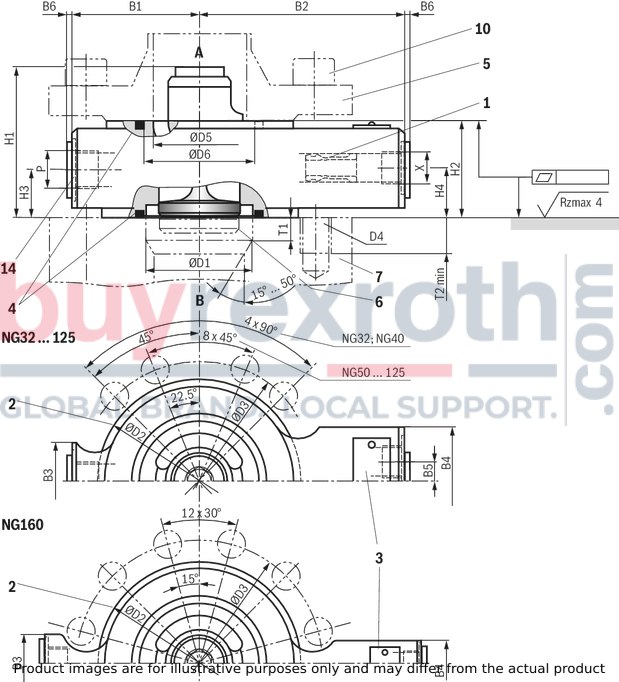

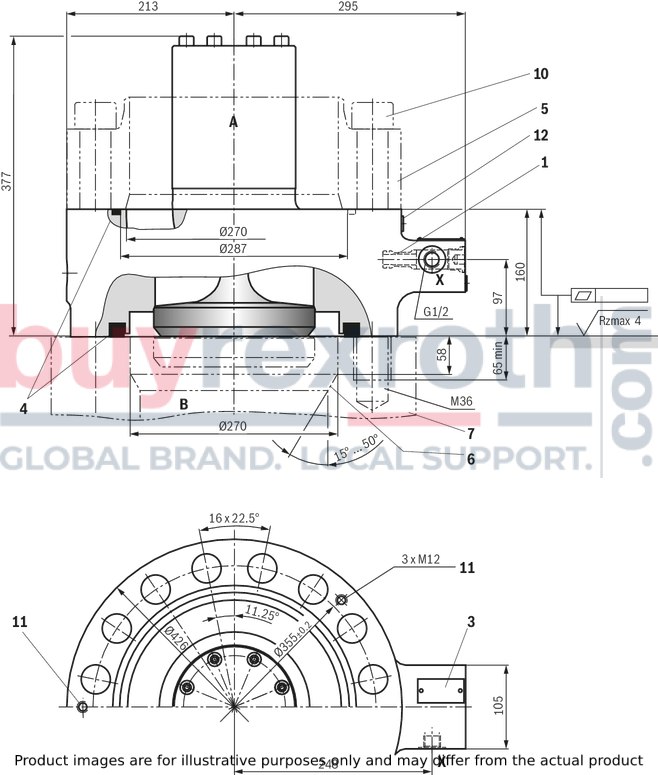

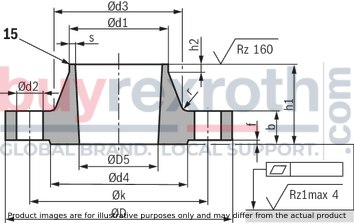

The Bosch Rexroth ZSF100F1-1-1X/M/01 (R900529340) is a pilot-operated check valve designed for integration into sandwich plate configurations. This model is part of the component series X, which is known for its robust performance and compatibility with high-pressure systems. With a maximum operating pressure of 315 bar and a maximum flow rate tailored to the system requirements, this check valve ensures reliable operation in demanding hydraulic circuits.

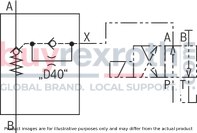

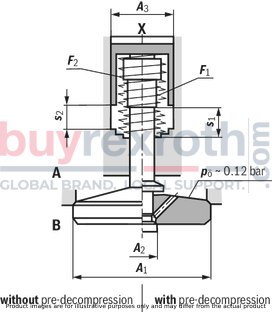

The ZSF100F1-1-1X/M/01 features an integrated throttle check valve, offering precise control over fluid flow and preventing reverse flow until pressure is applied. It's designed to work seamlessly with directional valves, although it requires an appropriately sized nozzle in channel P of the upstream directional valve to function correctly; this nozzle must be ordered separately and sized according to the prefill valve schematics provided by Bosch Rexroth.

Users should note that noncompliance with these installation requirements can lead to increased dynamic loads that may adversely affect the lifespan and performance of the valve. When installed correctly, this Bosch Rexroth check valve offers a reliable solution for managing fluid control in hydraulic systems where preventing backflow is critical, ensuring smooth and efficient machinery operation.

$3,900.00 USD

More are expected on July 10, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $3,802.50 USD | $97.50 USD |

| 25+ | $3,705.00 USD | $195.00 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as July 10, 2026 when ordered in