4WRPNH6C3B40L-2X/M/24FA6T

Manufacturer: Bosch Rexroth

Material #: R901302671

Model : 4WRPNH6C3B40L-2X/M/24FA6T

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

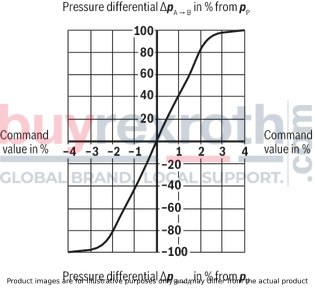

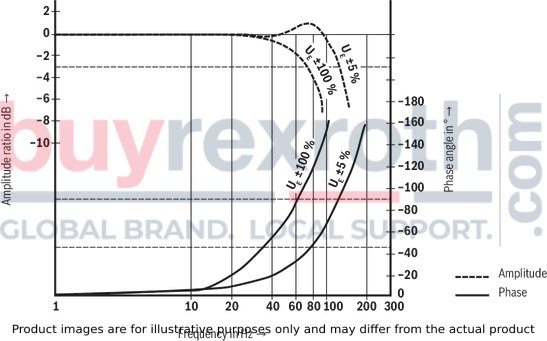

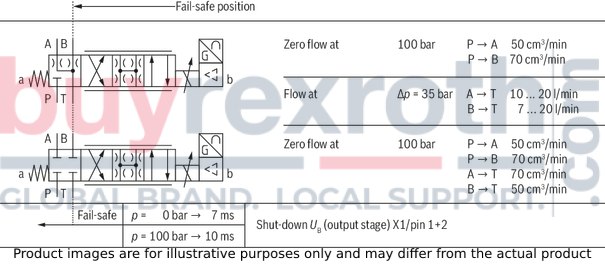

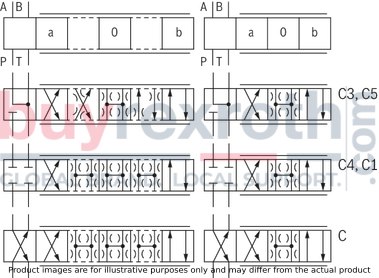

The Bosch Rexroth 4WRPNH6C3B40L-2X/M/24FA6T (R901302671) is a state-of-the-art high-response directional valve, equipped with integrated digital axis control (IACR) for precise motion control in hydraulic systems. This direct-operated valve features a control spool and sleeve of servo quality, ensuring reliable and accurate performance. It is designed to facilitate position control with an underlying velocity control and offers DSC functionality.

The valve's advanced design includes an analog sensor interface for current and voltage, as well as digital sensor interfaces that support various length measurement systems such as 1x length measurement system 5Vpp, SSI, or EnDat 2.2. Additionally, the product boasts clock-synchronized command value presetting in line with the PROFIdrive profile V4.1 and supports Telegram 401 or 402 for seamless integration into PROFIBUS DPV1 and DPV2 networks.

For diagnostics and parameterization, the Bosch Rexroth valve can be interfaced with the WinHPT commissioning software, which offers user-friendly data management on PCs running Windows 7 or Windows XP operating systems. The software simplifies project planning tasks and streamlines the setup process for optimal performance.

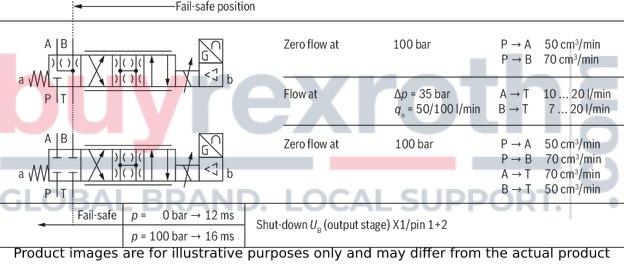

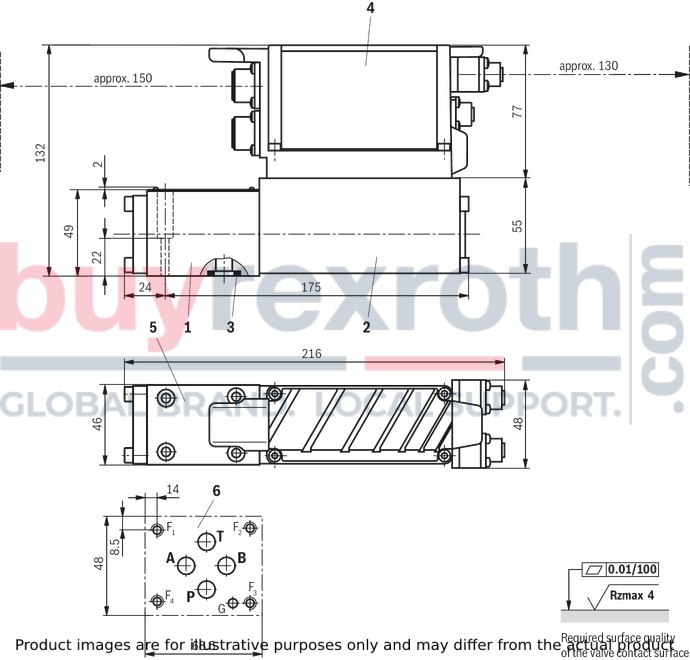

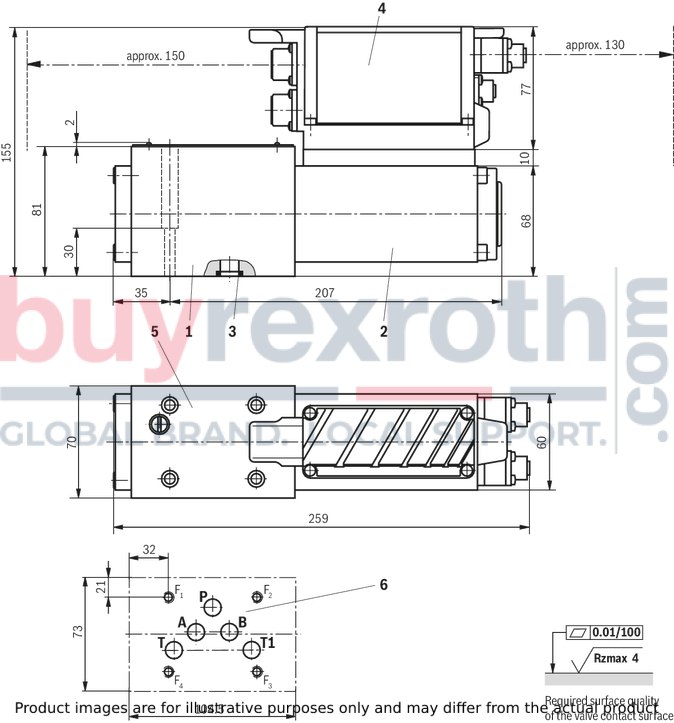

With a size of 6, component series X, maximum operating pressure of up to 315 bar, and maximum flow capacity of up to 40 l/min, this high-response valve is engineered to deliver robust performance in demanding applications. Its integrated electronics facilitate error detection such as cable breakage, undervoltage conditions, temperature monitoring of the electronics, communication errors, watchdog function, and synchronous monitoring.

Additional functionalities include error output at 24 V or control of an isolator valve, actuating variable adaptation, dead band compensation, zero point correction, valve inflection compensation, friction compensation with direction-dependent amplification along with PIDT controller settings and state controller options. The device also supports automatic or semi-automatic drive measurement for simplified controller optimization.

| Qty | Price | Savings |

|---|---|---|

| 5+ | $0.00 USD | $0.00 USD |

This product is not available. CLICK HERE to create a support ticket for us to locate your part or a suitable replacement